Spout Pouch Packing Machine

Product category

Range of Spout Pouch Packing Machine

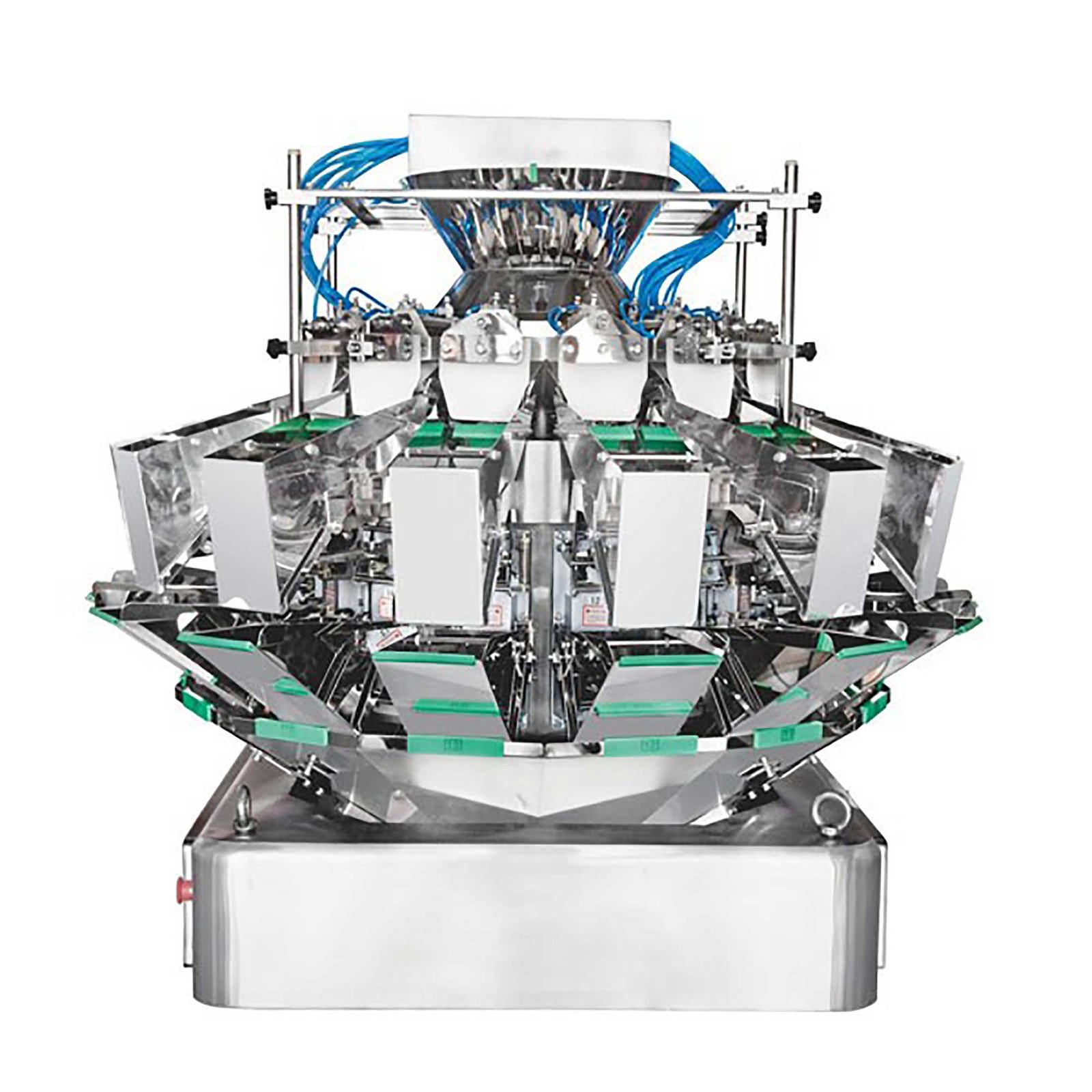

4-6 Head Filling Machine

Pneumatic Siemens

PLC control

Spout Top Filling machines are used to pack different forms of liquids & paste in preformed

spout pouches.

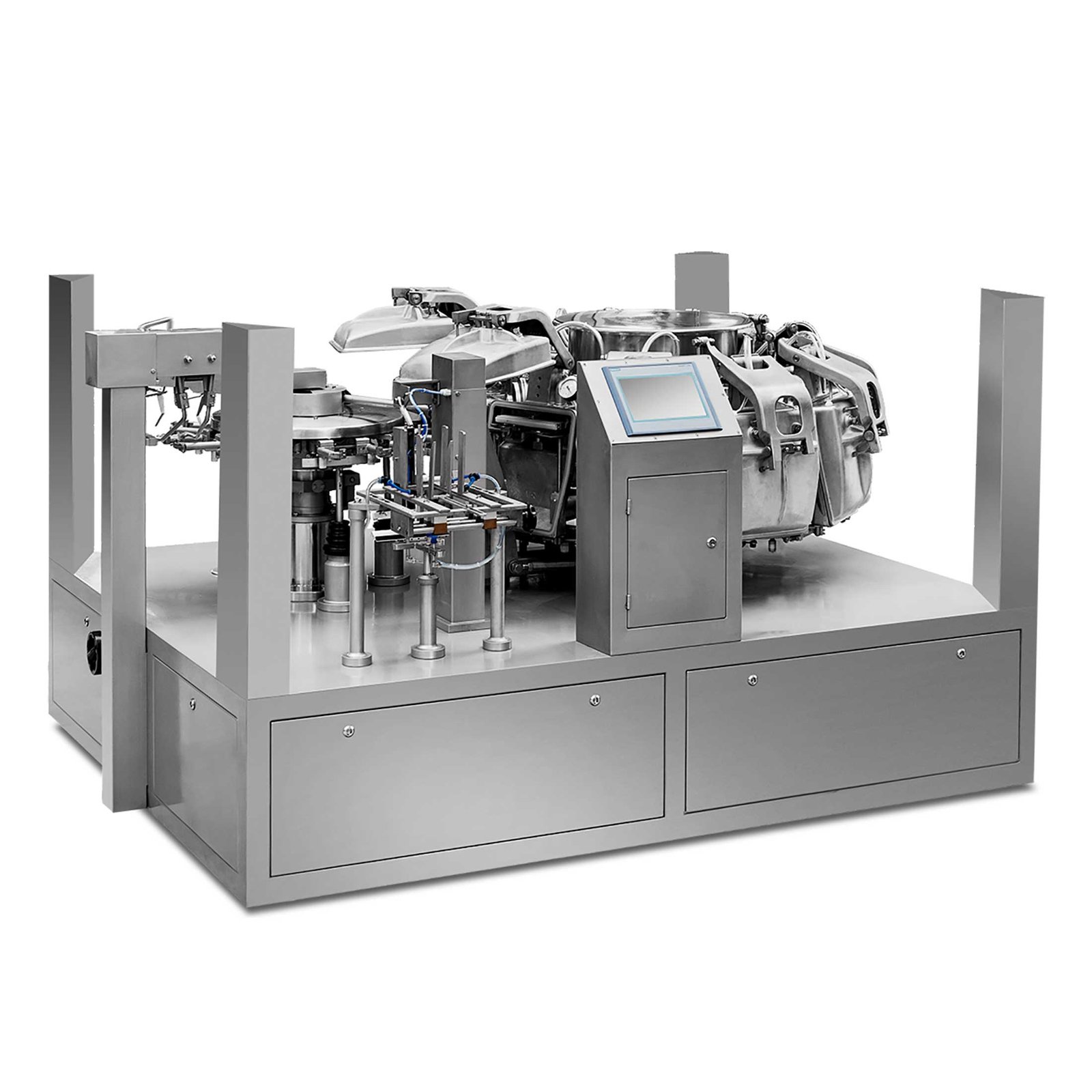

Spout HFFS Packing Machine

Automatic Material-Level

Control System

Spout HFFS Packing Machine for spout pouches is used to form, fill, and seal pouches with spouts in a horizontal orientation.

Ultra High Speed Filling Machine

Automatic cover arranging

and covering

They can achieve packaging speeds of hundreds of pouches per minute, depending on the product type and packaging size.

Spout Fixing - Sealing Machine

Spout Inserting and

Sealing Machine

Flexible pouch auto spout sealing machine is one kind of automatic device for install and seal plastic spout with premade pouch.

Suitable Bag Types:

Spout Pouch Liquid-Paste Packing Machine

Ultra Advance Full automatic 4-12 Head Stand-up Spout pouch filling and capping machine to fill all kinds of liquid, such as fruit juice, milk, detergent, beverage, Jelly, Yoghurt, Ketchup, Sauces, mayonnaise etc.

Flow-Process : Auto feeding pouch → Auto Filling → Auto Cleaning nozzle and dry → Auto feeding cap → Auto Tightening → Auto output the pouch

Process and Material

- Transmission system: Medium-large gear reduction motor is used for driving, and direct connection transmission is adopted. The transmission system is simple, accurate in positioning control, convenient to adjust through touch screen parameters, and strong in adaptability. Adopt mechanical anti-jamming safety protection device to ensure the normal operation of the machine. Speed regulation with Schneider inverter;

- Filling part (users can select servo motor + electric cylinder for quantitative filling and touch screen for adjusting filling quantity)

- Cleaning of bag mouth: stainless steel plug-type nozzle water inlet prevention design is adopted. Downward movement has buffering and positioning to avoid crushing the nozzle. Cleaning nozzle is installed on the side. Blowing has no dead angle. Opposite injection type cleaning mechanism. Cleaning water and blowing are synchronously and intermittently sprayed with the whole machine. Cleaning is complete without liquid accumulation. The device is all made of stainless materials.

- Automatic cover arranging and covering: Use electromagnetic vibration to arrange the covers from the track in sequence, Track can be fine-tuned when the nozzle moves, it will automatically cover, set up optical fiber without cover detection, and automatically alarm and stop without cover.

Automatic capping (user can select servo motor for direct connection and independent capping): electric capping mechanism, Taiwan motor, gear transmission, 12-head linkage, permanent magnet torque adjustment, capping head driven up and down by air cylinder, accurate positioning and guidance, capping head with buffer to avoid damaging nozzle, capping device with adjustable up and down, left and right positions as a whole - Automatic bag withdrawal: stop blocks are used to automatically withdraw bags and buffer chutes are provided.

- Code spraying: reserve the installation position of the code spraying machine, and the user can configure the code spraying machine himself

- Low-pressure protection: Low-pressure protection technology is adopted to prevent the machine from starting at low pressure and to provide the reliability and stability of the machine. In case of low air pressure during machine operation, the machine will automatically stop for protection.

Suitable Product