Online Inspection System

Product category

Our Range of Online Inspection Systems

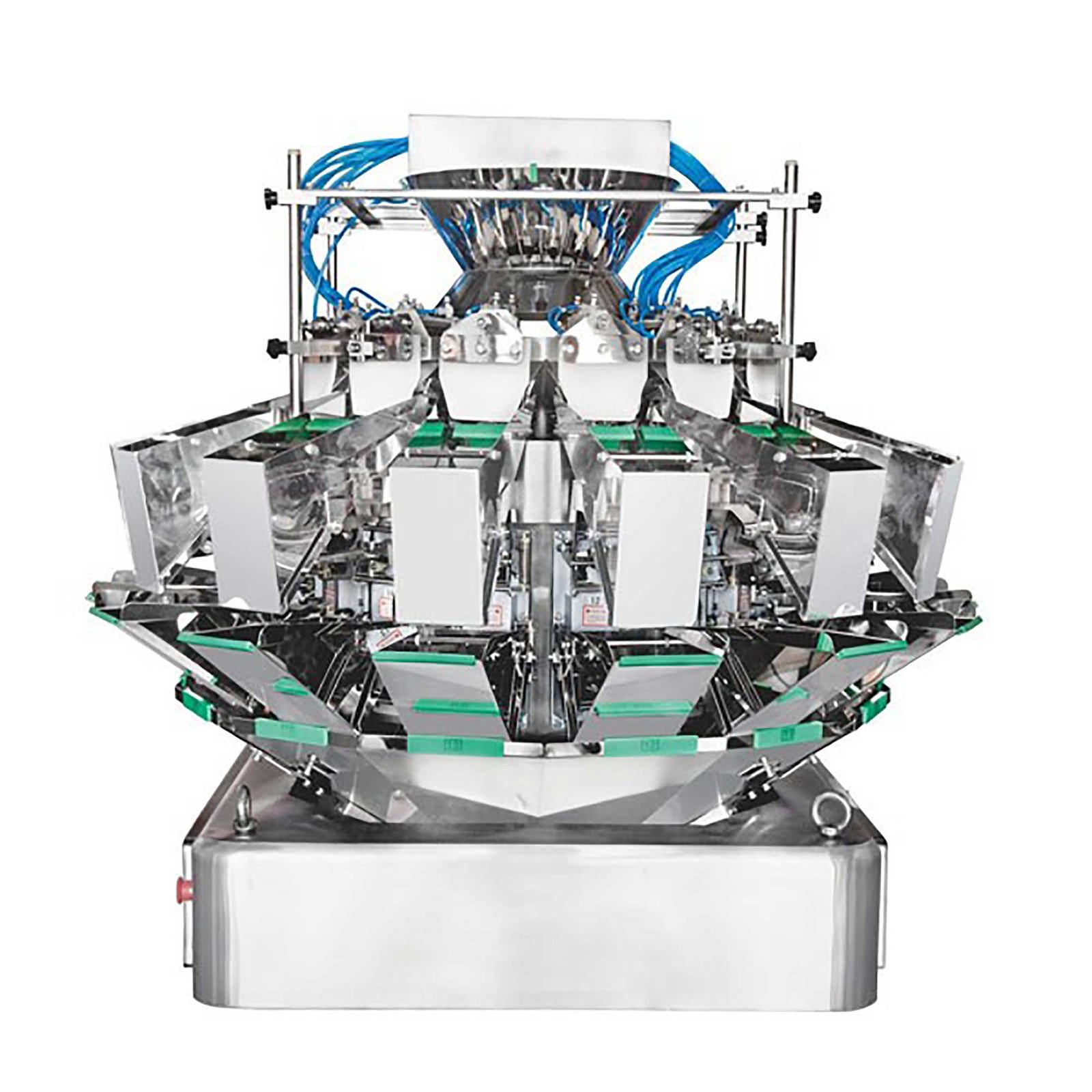

Online Metal

Detector

Online Horizontal

Metal Detector

Metal Detector Series is suitable for all types of not metallic Bags, Cartons, packaging of different sizes and shapes.

X-Ray Inspection System

Foreign containment

X-ray inspection machine

X-Ray foreign containment inspection, positively introduce leading technologies into highly sensitive, easy-to-operate.

Online Check Weigher

Individual products in the

production line

Online Check Weigher has a wide weighing range & adopts the intelligent design with the function of automatic adjustment.

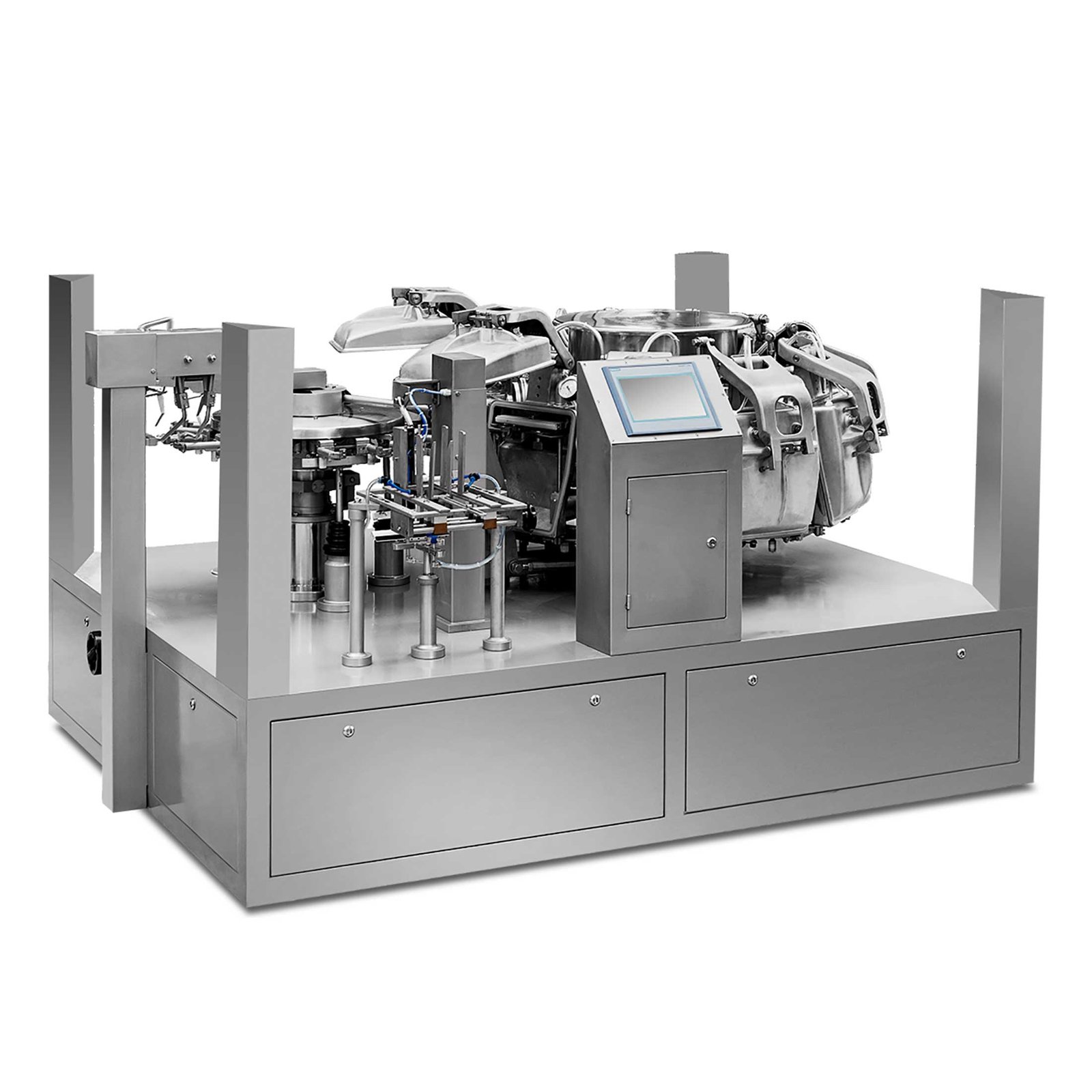

Combine Metal Cum Check Weigher

Flexibly matched with

different removal methods

It supports the unlimited speed regulation function of different speed requirements for special environment applications.

Online Inspection Systems

We are one of the leading Suppliers for Check weighers / Metal Detectors / X-Ray Machines. We have been specialized in R&D & marketing various high speed and precision check & correction systems, and provided our customers with professional and all-round service. As a leading supplier, we try our best to offer new quality Check weigher, Automatic weigher, Combination weigher, linear scale, Metal Detector system , X-ray Systems etc. according to our customers’ requirement.

We have range of various high speed and precision check & correction systems as Check weighers / Metal Detectors / X-Ray Machines to accompany for our packaging solutions. For any consumer products & packed food industry, its very important that the product placed in market must have accurate weight and must be free from any foreign contamination like metal, glass, insects etc.Our inspection sytems not only helps you to examine your product for such errors and foreign contamination but also makes your brand more reliable and trust worthy amoung your consumers. These all equipment are custom designed as per various industrial requirements.

An online metal and weight inspection system is a technological solution used in various industries to inspect and ensure the quality of products related to metal components and their weight. This type of system employs advanced sensors, cameras, and algorithms to detect and analyse metal defects, as well as accurately measure the weight of products during the manufacturing or production process.

Key components of an online inspection system may include

- Metal Inspection Sensors: These sensors are used to detect and identify metal defects such as cracks, voids, inclusions, and surface irregularities. They utilize different technologies, including eddy current testing, magnetic particle inspection, ultrasonic testing, and X-ray inspection, depending on the specific application and requirements.

- Weight Measurement Systems: Weight sensors are employed to accurately measure the weight of products, ensuring they meet specified weight criteria. This is crucial for industries where weight compliance is critical, such as in food packaging or shipping.

- Conveyor Systems: The products under inspection are usually transported on conveyor belts or other handling mechanisms through the inspection area. This allows for continuous and automated inspection of a large number of items.

- Image Processing and Computer Vision: Sophisticated image processing and computer vision algorithms are used to analyse the visual data captured by cameras during the inspection process. This helps in identifying metal defects and analysing the weight of products accurately.

- Data Analysis and Reporting: The system’s software analyses the collected data, compares it against pre-defined quality standards, and generates reports. It can categorize products as “pass” or “fail” based on the inspection results.

- Real-time Monitoring and Integration: The system may provide real-time monitoring and integration with the production line or factory control systems. This enables immediate corrective actions if any issues are detected, reducing waste and improving overall production efficiency.

- User Interface: The system may have a user-friendly interface that allows operators to set parameters, monitor the inspection process, and review inspection results.

Industries that benefit from Online Inspection Systems include manufacturing, automotive, aerospace, electronics, food and beverage, pharmaceuticals, electronic, pharmaceutical, food, beverage, health products, daily chemical, light industry, agricultural and side-line products, and more. These systems help ensure product quality, reduce production costs, prevent defective items from reaching the market, and comply with industry regulations and standards.

Features

Adapt phase discriminating technology that can effectively refrain product effect; Adapt advanced DSP technology and leading intelligent algorithm which can improve detection sensitivity and promote stability of the machine; Be able to detect various metals like iron, stainless teel,copper and aluminum, etc; LCD display, English & Chinese operating menu; Self-learning function contributes to automatically choose suitable working parameters according to different products; Memory function for registering various products(Max: Over 20 Items); Simple conveyor structure makes it convenient to disassemble and assemble; Special design of conveyor belt to avoid deviation; Made of stainless steel, fairly good waterproof ability; Excellent quality with attractive price.

Note: The technical parameter above namely is the result of sensitivity by inspecting only the test sample on the belt. The sensitivity would be affected according to the products being inspected and working condition. Requirements for different sizes by customers can be fulfilled. Chain conveyor is selectable.

Adapt phase discriminating technology that can effectively refrain product effect.

- Adapt advanced DSP technology and leading intelligent algorithm which can improve detection sensitivity and promote stability of the machine.

- Be able to detect various metals like iron, stainless steel, copper and aluminium etc.

- LCD display, English & Chinese operating menu.

- Self-learning function contributes to automatically choose suitable working parameters according to different products.

- Memory function for registering various products (Max: Over 20 Items).

- Simple conveyor structure makes it convenient to disassemble and assemble.

- Special design of conveyor belt to avoid deviation.

- Made of stainless steel, fairly good waterproof ability.

- Excellent quality with attractive price.

Application

The metal detector is widely used in Aquatic products, meat and poultry products, preserved food, flour products, dried fruit, vegetables , chemical materials , medical drugs, cosmetics, toys and primary products, etc..