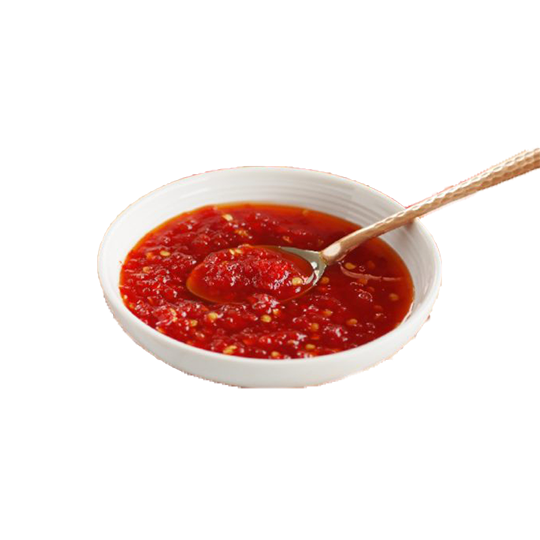

Liquid/Paste Can Packing Machine

Product category

Automatic Paste Jar – Bottle Packing Machine

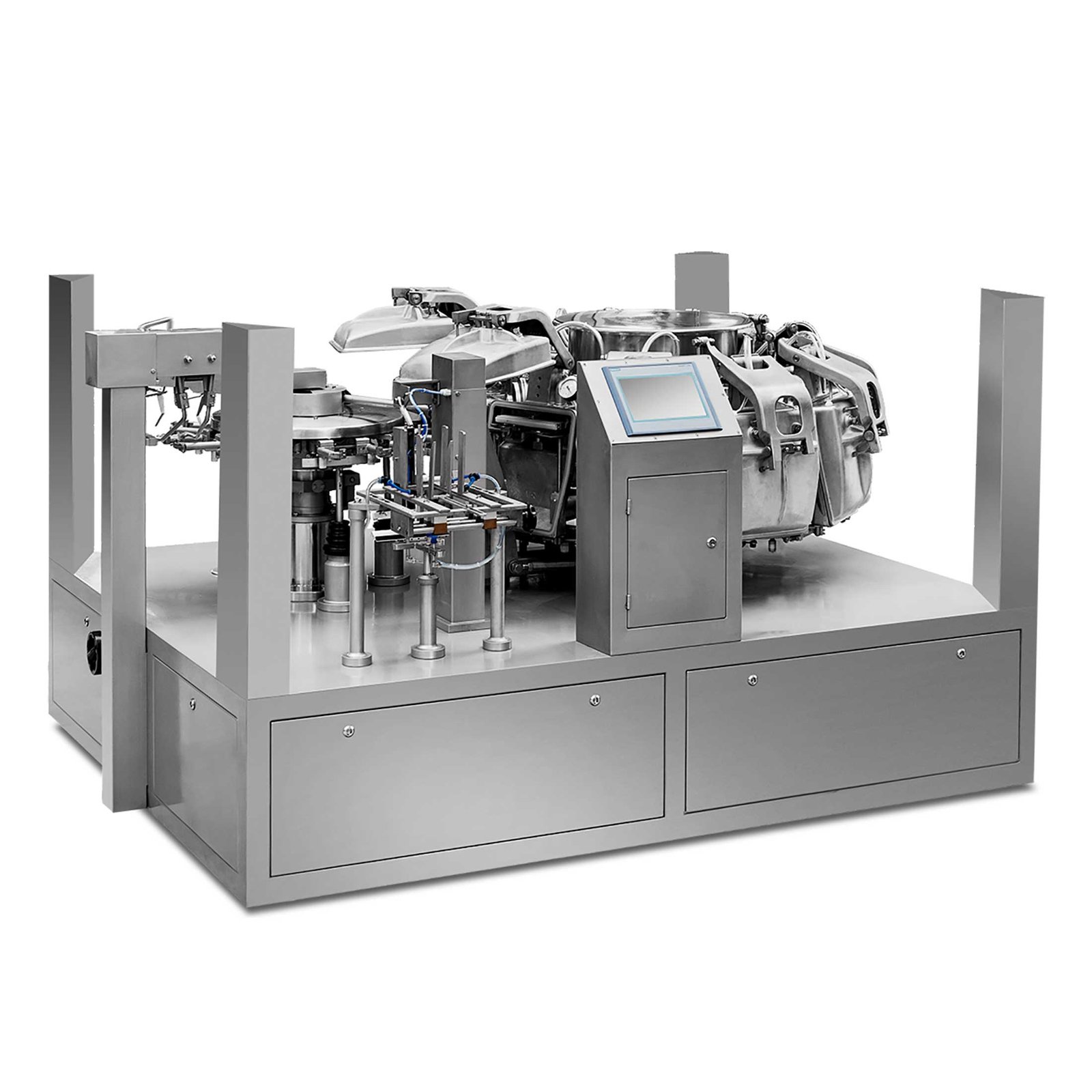

Automatic Liquid – Paste Jar – Bottle Packing Machine are the perfect solution for packaging of all type of Tin-Glass Jars irrespective of it’s shapes and sizes. These Machines streamline your operations and increase output. These latest and innovative Jar Packaging Machines can also perform online vacuum with more advance system. The end result – your packaged product looks modern, offers convenience, and differentiates itself from your competition.

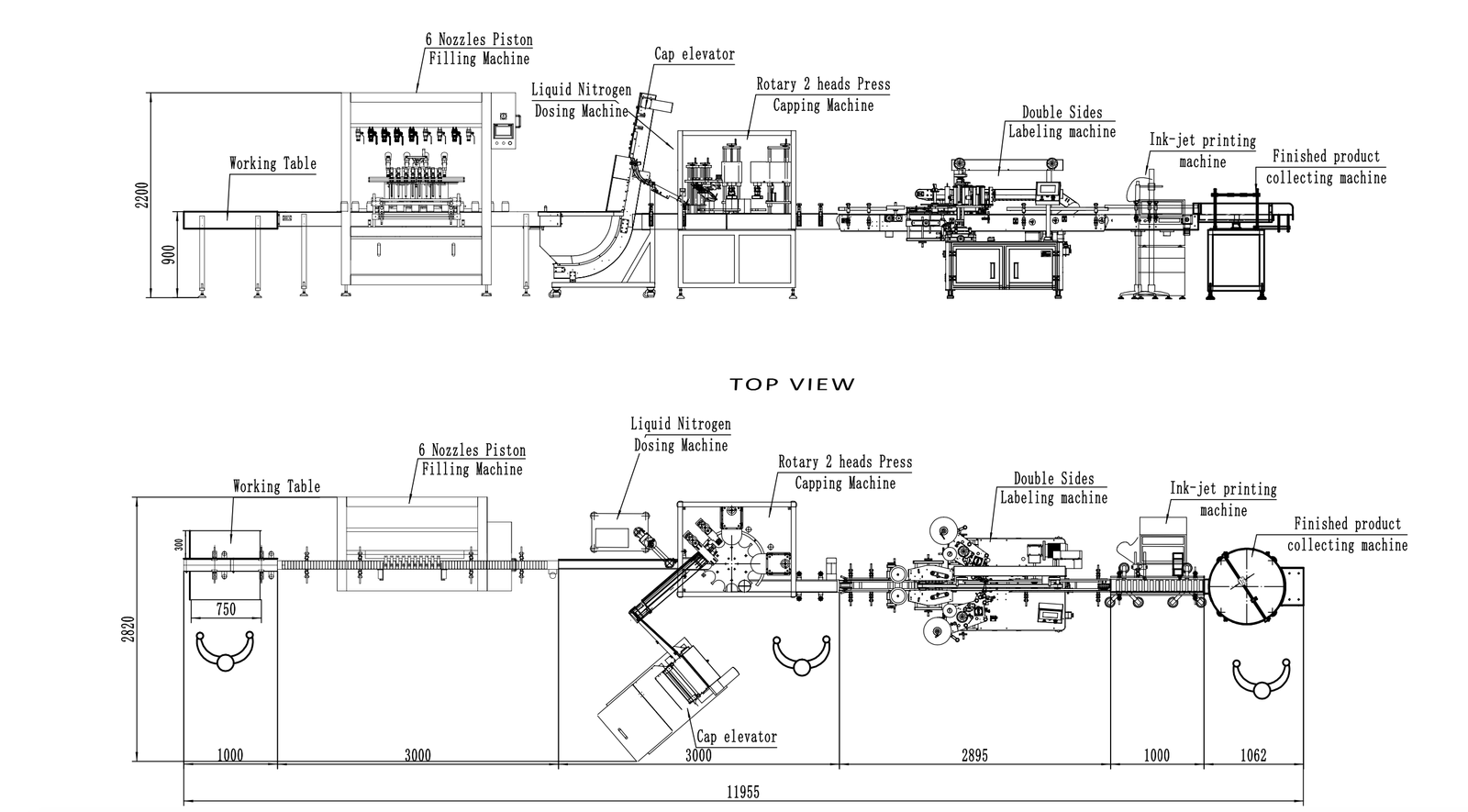

The production line includes liquid filling and capping .The automation is high. They can be adopted for the part of packaging system. These Paste filling machine can be designed to many kinds of filling machine with different principle according to liquid character. The fabrication technology is very sophisticated and the processing is very accuracy. The components from international famous brands are adopted for the whole machine which is made of 304 stainless steel with high packaging accuracy and stable and reliable performance.

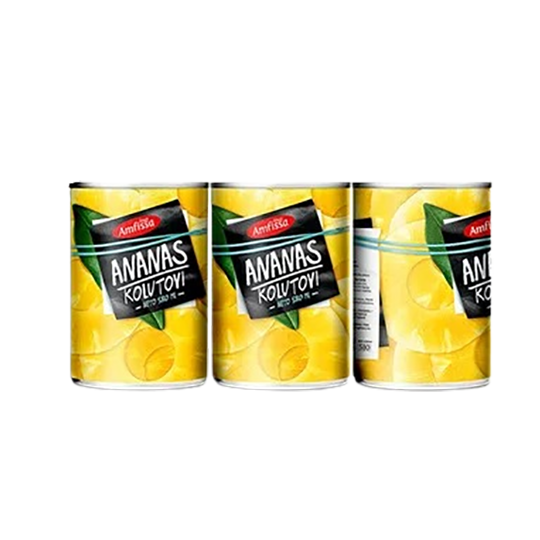

Imperial supplies high quality Powder Jar Filling and Packaging equipment worldwide, that meets your needs, optimize your production line, and ensure the production quality of your products. These Automatic Jar Packing Machine is a specialized packaging machine designed to efficiently pack powder products into jars automatically. These machines are commonly used in food processing and packaging industries to streamline the packaging process and improve productivity.

Enquire Now

Suitable Jar

Key features of Automatic Solid Product Jar Packing Machine may include

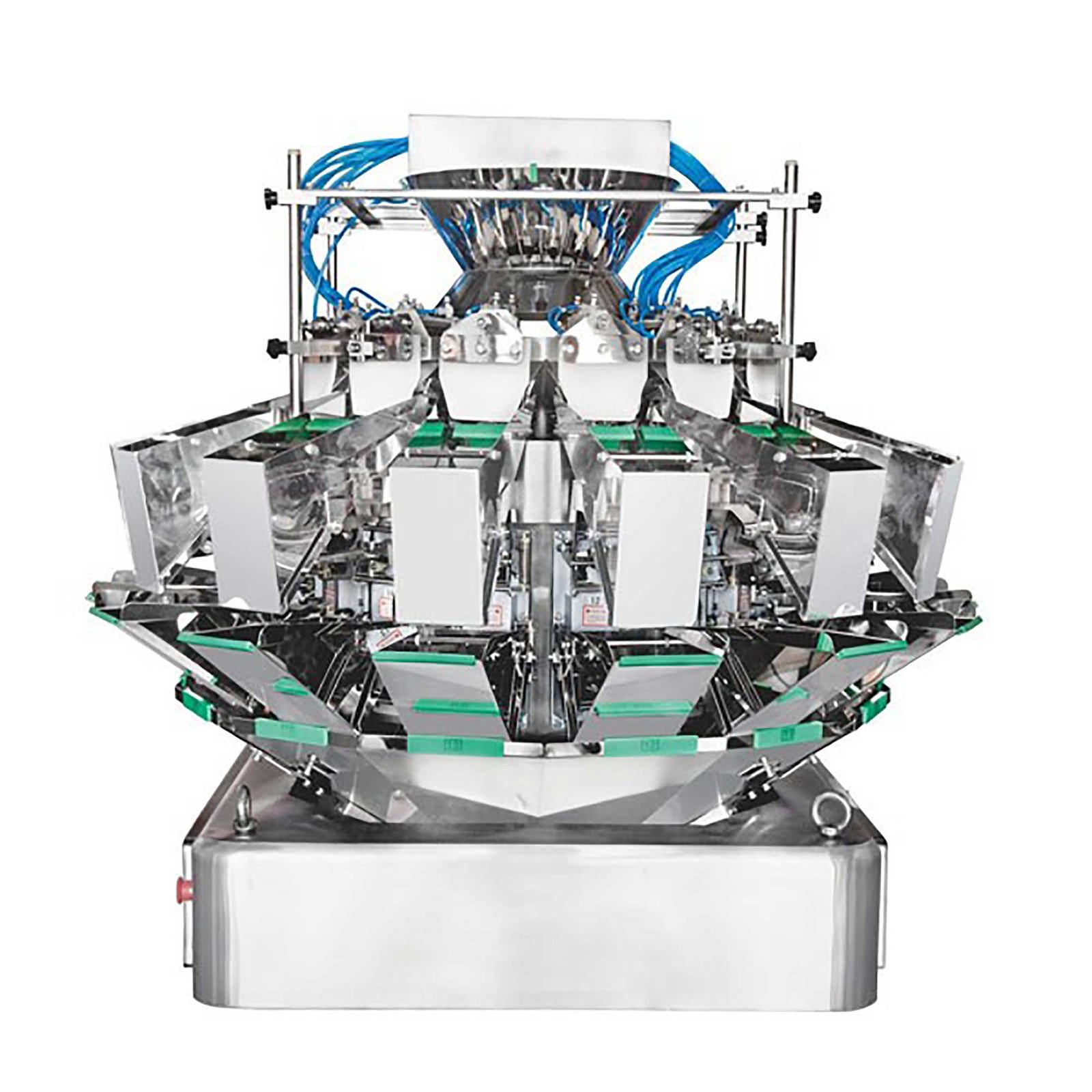

- Hopper: A hopper is used to hold and feed the dry fruits or granular products into the packaging machine.

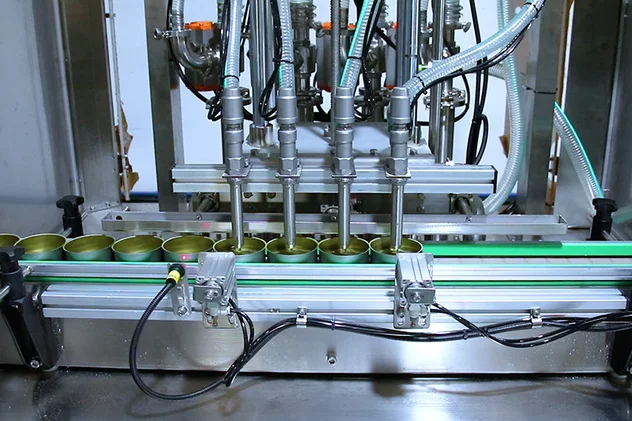

- Conveyor system: The machine may be equipped with a conveyor system to transport the empty jars to the packaging station and then move the filled jars away from the packaging area.

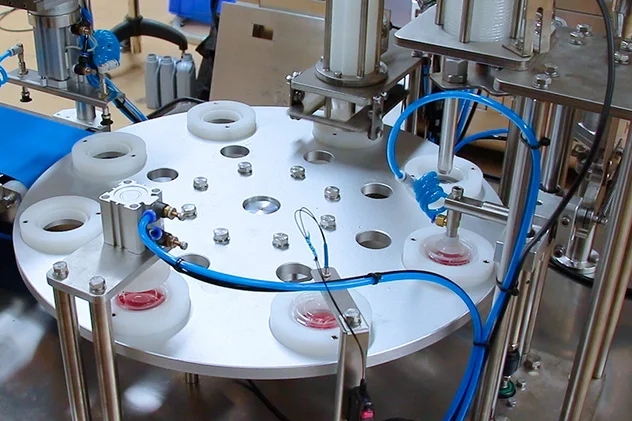

- Filling mechanism: The machine can have a filling mechanism, such as Piston Filler or volumetric fillers, to dispense the correct quantity of the product into each jar.

- Capping system: After filling, the jars are sealed using a capping system, which may include options for different types of caps or lids.

- Labeling system: Some machines may also come with an integrated labeling system to apply labels to the filled jars automatically.

- Control panel: An easy-to-use control panel allows operators to set parameters, adjust settings, and monitor the machine’s performance during the packaging process.

- Speed and capacity: The machines can have varying production capacities, depending on the model and design, ranging from a few jars per minute to dozens or more.

- Material handling: The machine is usually made of stainless steel or other food-grade materials to ensure product safety and hygiene.

- Customization: Some machines may offer customization options to accommodate various jar sizes and types of dry fruits or granular products.

Benefits of using an Automatic Granular Product Jar Packing Machine

- Increased efficiency: These machines significantly speed up the packaging process compared to manual methods, leading to higher productivity.

- Consistency: Automated machines ensure consistent filling and packaging, reducing product variations and enhancing overall product quality.

- Reduced labor costs: By automating the packaging process, businesses can reduce the need for manual labor, saving on workforce expenses.

- Hygiene and safety: Food-grade materials and automated processes help maintain hygiene standards, reducing the risk of contamination.

- Versatility: Many of these machines can handle different types of dry fruits and granular products, making them suitable for various applications.

- Space-saving: These machines are designed to occupy minimal floor space, optimizing the utilization of the production area.

Packaging Process

Suitable Products