Corrosive Liquid Bottle Filling System

Product category

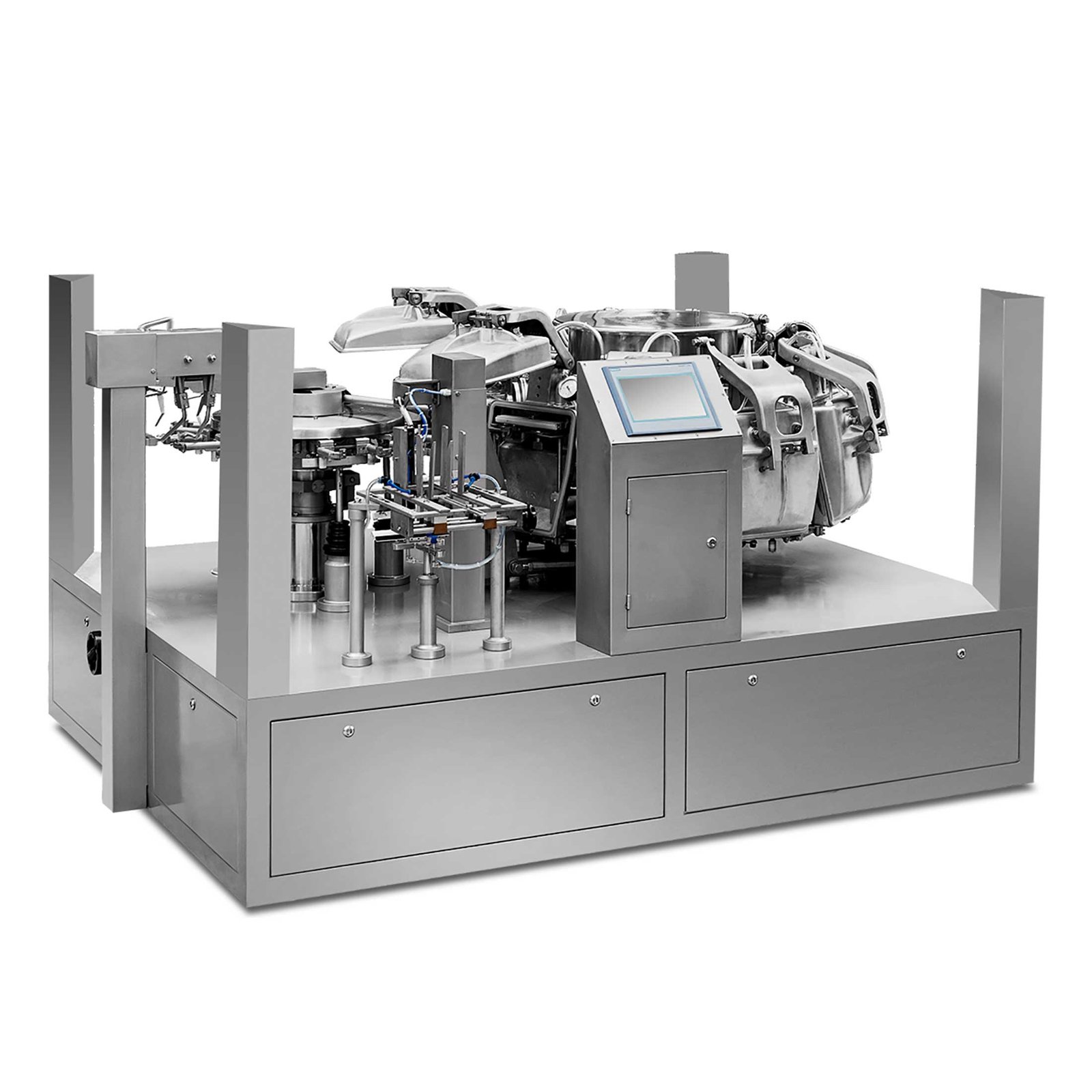

Automatic Corrosive Liquid Pet Bottle Packing Machine

Automatic Corrosive Liquid Pet Bottle Packing Machine are the perfect solution for packaging of all type of Tin-Glass Jars irrespective of it’s shapes and sizes. These Machines streamline your operations and increase output. These latest and innovative Jar Packaging Machines can also perform online vacuum with more advance system. The end result – your packaged product looks modern, offers convenience, and differentiates itself from your competition.

Designing a Fully Automatic Jar Bottle Packaging Machine for corrosive liquids like handwash, Liquid Detergent, Floor Cleaner, Toilet Cleaner etc. requires careful consideration of the materials used and the safety measures implemented. Corrosive liquids can be hazardous, so ensuring the protection of both the operators and the equipment is crucial.

The production line includes liquid filling and capping .The automation is high. They can be adopted for the part of packaging system. These highly corrosive filling machine can be designed to many kinds of filling machine with different principle according to liquid character. The fabrication technology is very sophisticated and the processing is very accuracy. The components from international famous brands are adopted for the whole machine which is made of 304 stainless steel with high packaging accuracy and stable and reliable performance.

Enquire Now

Suitable Jar

Some of the Corrosive Liquid Jar Filling – Packaging Options

- Liquid Detergent Filling Machine

- Floor Cleaner Filling Machine

- Disinfectant water filling machine

- Lubricating oil filling machine

- Ink filling machine

- Hand Wash Filling Machine

- Phenyl Filling Machine

- Hand Sanitizer Filling Machine

- Shampoo Packaging Machine

- Grease Filling Machine

- Toilet Cleaner Filling Machine

- Dish Wash Filling Machine

- Detergent Filling Machine

- Chemical Filling Machine

- Glue Filling Machine

Here's a high-level outline of the key features of Automatic Jar Bottle Packaging Machine

- Material Selection: The parts of the machine that come in contact with the corrosive liquid must be made of corrosion-resistant materials. Stainless steel, particularly 316-grade stainless steel, is a common choice for its resistance to corrosion.

- Sealing and Containment: The machine must have effective sealing mechanisms to prevent any leakage of the corrosive liquid during the packaging process. Double seals and gaskets can be used to enhance containment.

- Chemical Compatibility: Ensure that all components, including pipes, valves, and pumps, are compatible with the specific corrosive liquids being packaged. Some chemicals may react with certain materials, leading to potential hazards or deterioration of the equipment.

- Automation and Control: The machine should be fully automated to minimize human contact with the corrosive liquid. Programmable Logic Controllers (PLCs) can be used for precise control over the packaging process, reducing the risk of human errors.

- Safety Features: Implement multiple safety features, such as emergency stop buttons, leak detectors, and protective enclosures to safeguard the operators and prevent any accidents or spills.

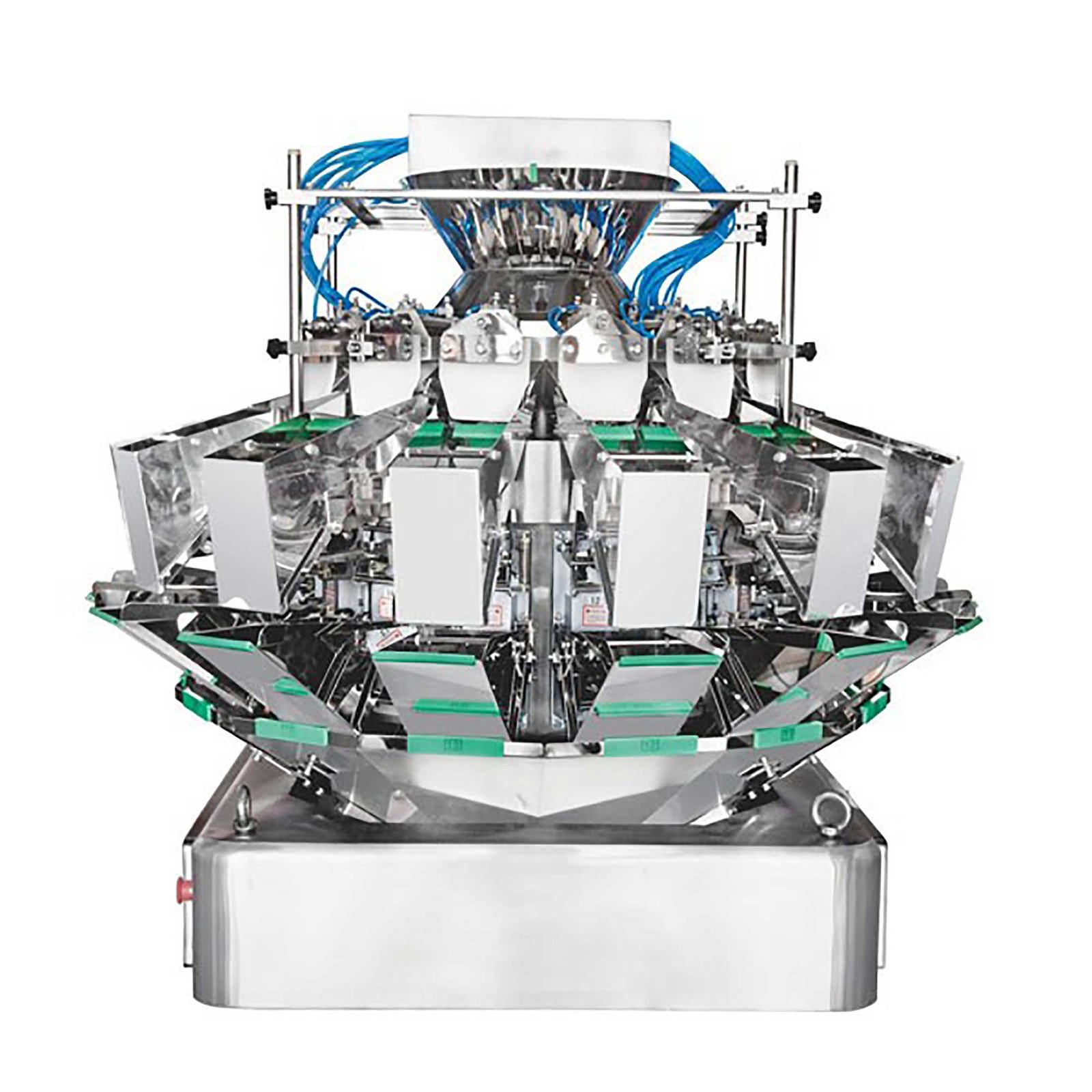

- Filling Mechanism: The filling mechanism should be designed to prevent splashing or foaming of the corrosive liquid during the filling process. Overflow filling or positive displacement filling methods are often used for liquids with these characteristics.

- Rinsing and Cleaning: Incorporate an efficient rinsing and cleaning system to prevent cross-contamination between different batches of corrosive liquids. Proper cleaning procedures are essential to maintain the longevity of the machine.

- Operator Training: Proper training of the machine operators is crucial to ensure they understand the potential hazards associated with corrosive liquids and know how to operate the equipment safely.

It’s important to collaborate with experienced engineers and specialists in Automatic corrosive liquid packaging machinery and chemical handling to design a robust and safe system for packaging corrosive liquids. Additionally, regular maintenance and inspections will be essential to keep the machine in optimal condition and prevent any potential issues that could compromise safety.

Packaging Layout

Suitable Products