Multihead Weigher

Product category

Types of Weighers

10 Head Weigher

Combination of high speed

and precision

10 Head Weigher offered comes with technically advanced weighing and filling support.

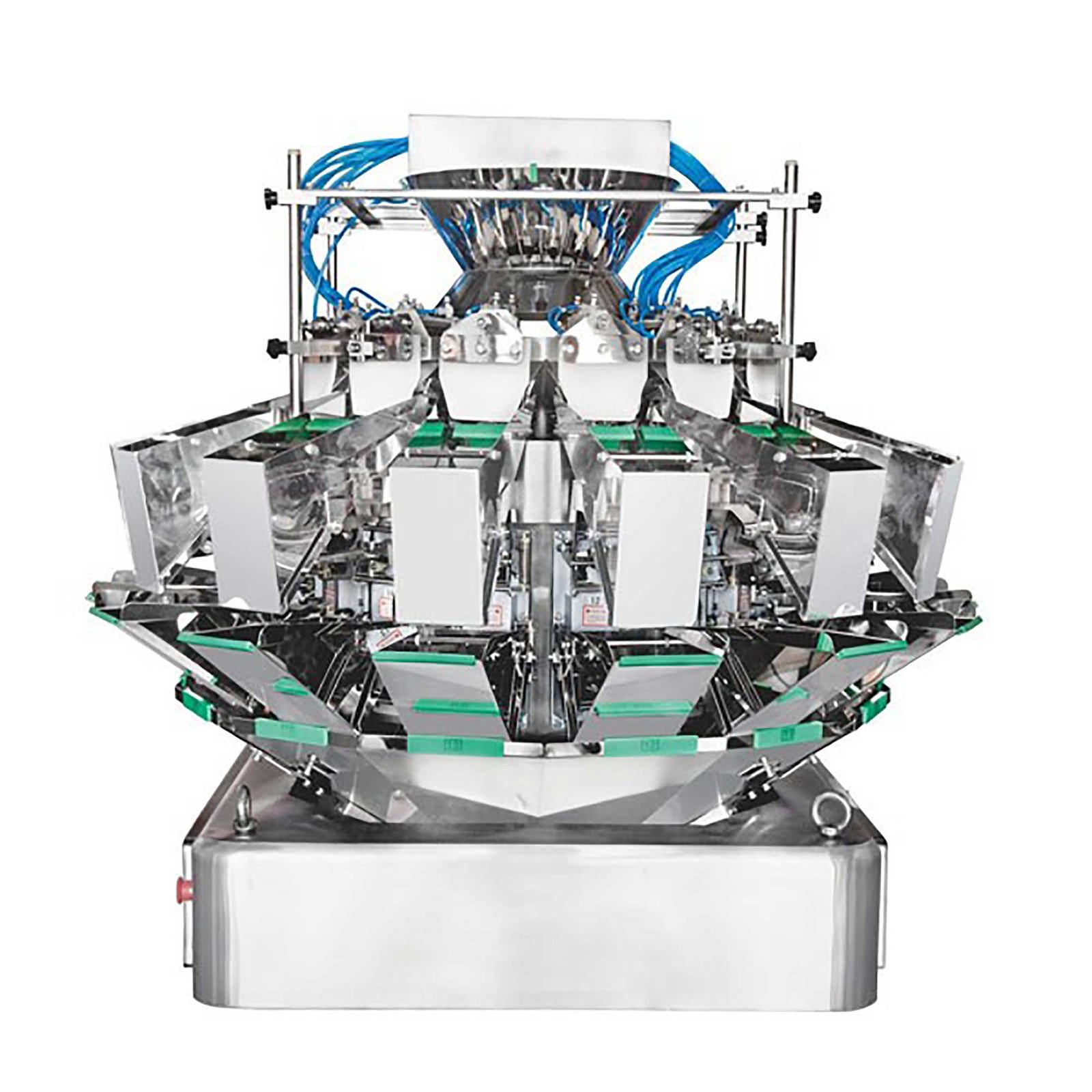

10-14 Head Mini-Weigher

Improve weighing stability

and accuracy

Low power consumption thus lowering running cost of machine.

24-32 Head Weigher

Mix different product in one

with perfection

Heavy Duty Load Cell, Drastically Reduce Products Giveaway.

14 Head Weigher

Adopt high precision &

High accuracy

The Multihead Weigher Packing Machine provides leak proof pouches.

WaterProof Weigher

IP65/66 Protection from

Water & Dust

Fully designed for all types of environments especially with high amounts of humidity.

Special Application Weigher

Weighing Complex

Product with Perfection

Capable of weighing, mixing and counting with greater accuracy at high speeds.

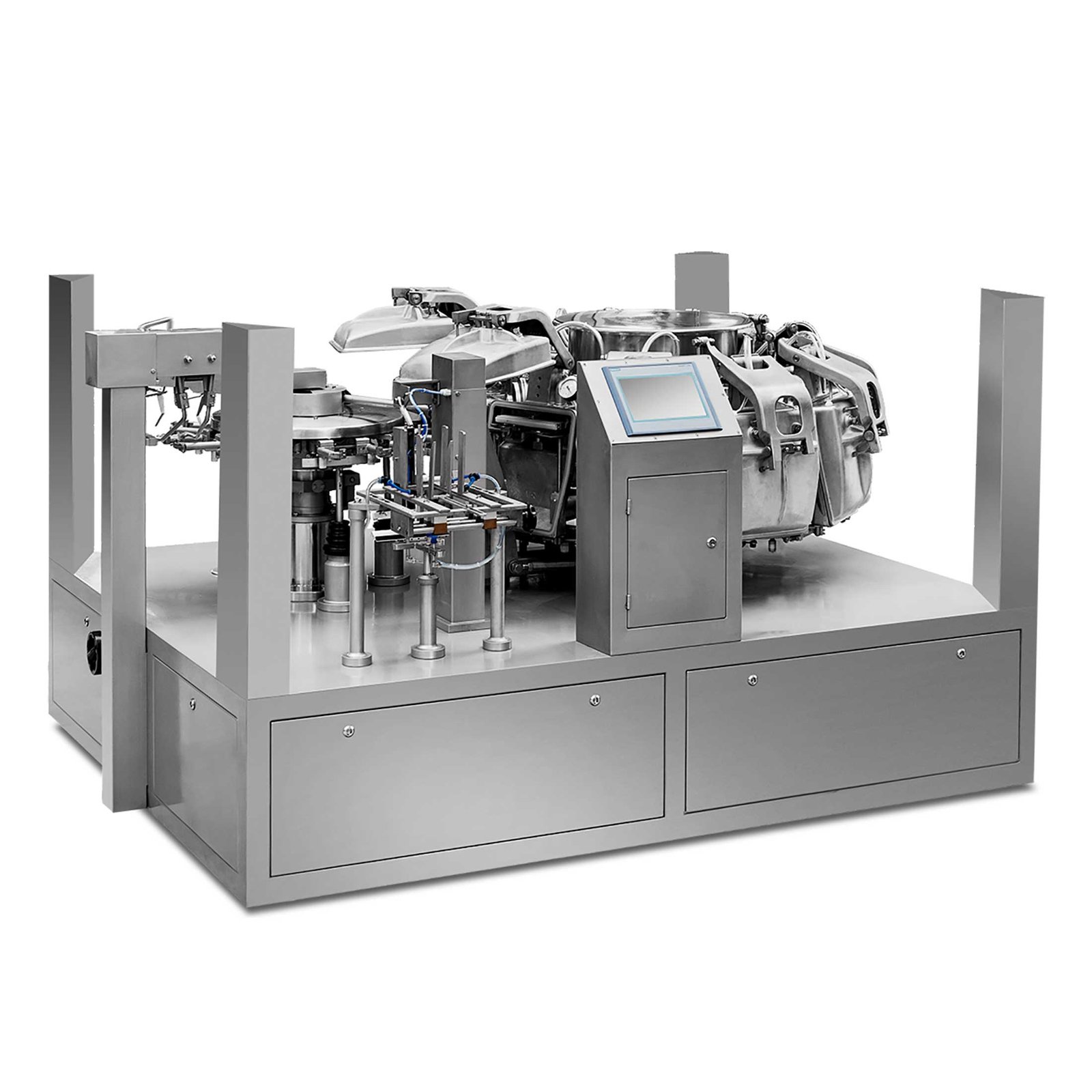

Multihead Weigher

Imperial been specialized in Multihead Weighers with the combination of high speed and precision, and provided its customers with professional and all-round service, Imperial has become the most trusted brand among the Multihead users & packaging OEMs. As a leading Multihead Weigher supplier, Imperial try its best to offer new quality weighing machine, Linear weigher, Check weigher, Automatic weigher, Combination weigher, linear scale system according to our customer’s requirement. To serve the needs of our customers across a wide variety of industries, Imperial provides both automatic multi-head weighers and semi-automatic multi-head weighers for food and non-food applications.

Automatic Multihead Weighers are capable of weighing, mixing and counting with greater accuracy at high speeds, which makes them an ideal choice for large production lines and complicated application mixtures such as mixed bags of snacks, confectionery or fruit and nuts. Imperial has been at the forefront of multihead weighing technology for many years, and proudly supply the very high quality multihead weigher with load cells. Imperial has worked continuously to bring innovative and revolutionary multihead weighers to the industry, to help make weighing easier and more efficient than ever before. We supply Multi heads from 10-20 heads.

Applications

Sticky products:Fresh meat and fish, whether in a sauce or not, poultry and cheese (including grated cheese) can be moved along by using belts or screw feeders rather than vibration.

Granules and powders:While free-flowing, fine-grained powders can be weighed more cheaply by other means (such as cut-gate or linear weighers, or volumetric feeders), granules such as coffee granules and products such as loose tea can be weighed on today’s multiheads.

Fragile products:Weighers with more shallow angles of descent and various cushioned inserts have made it possible to pack delicate and brittle items such as hand-made chocolates and gourmet biscuits.

Complex products:Using mix-weighing combined with a distribution system tailored to deliver separate components into a tray, a ready meal can be assembled with just the right quantities of, say, rice, meat and vegetables in the appropriate compartments.

History & Applications of Multi-Head Weigher

The multihead weigher was first invented and brought to market in the early 1960s.

Multihead weighers were used initially for weighing certain vegetables. Their use expanded exponentially in the 1970s and 1980s when they were applied to the rapid weighing of snacks and confectionery into bags. What cherry tomatoes and crisps had in common was that they flowed easily through the machine and into the pack, with no more encouragement than gravity and a moderate level of vibration of the feeders. Since then, the accuracy and relative speed have been extended to many products which would in the early days of the technology have been seen as difficult to handle.

Today this kind of machine, thanks to its high speed and accuracy, has widely spread in the packaging industry and is produced worldwide by a number of manufacturers. Some manufacturers offer complete packaging lines, integrating the multihead weigher with other packaging machinery ranging from bagmakers (including Vertical Form Fill and Seal bagmakers) to traysealers and inspection systems. The latter include checkweighers and X-ray inspection systems.

Weighers