Nuts Processing Plant

Healthy yet Delicious : Dry-Fruits & Nuts Processing Machines

Nuts and dry fruits processing machines are specialized equipment designed to handle various stages of processing, sorting, cleaning, roasting, and packaging nuts and dry fruits. These machines are commonly used in the food industry to improve efficiency and maintain the quality and safety of the products.

Designed with our customers in mind, the nut processing System uses the latest technologies and applies our expertise to shorten nut roast times by up to 60% when roasting almonds, pistachios, cashews, and other tree nuts. We’ve taken the time and effort to ensure that our nuts processing machines can increase product yield and produce a consistent crunch on all nut types. The modular and easy access build prioritizes food safety and cleanability, all while maintaining energy efficiency during operation. Because at the end of the day, simply selling products has never been enough.

Customizing these machines for the specific needs of each customer and product is essential. Collaboration with experts in food processing and packaging machinery will help ensure the machines meet industry standards and deliver high-quality roasted nuts and peanut butter.

Enquire Now

Final Output Products

Fully Automatic Nuts Processing Machines

Below are some common types of nuts and dry fruits processing machines.

1. Continuous Nuts Roasting Machines: Roasting enhances the flavour and aroma of nuts and dry fruits. Roasting machines use hot air or direct heat to evenly roast the products without burning them.

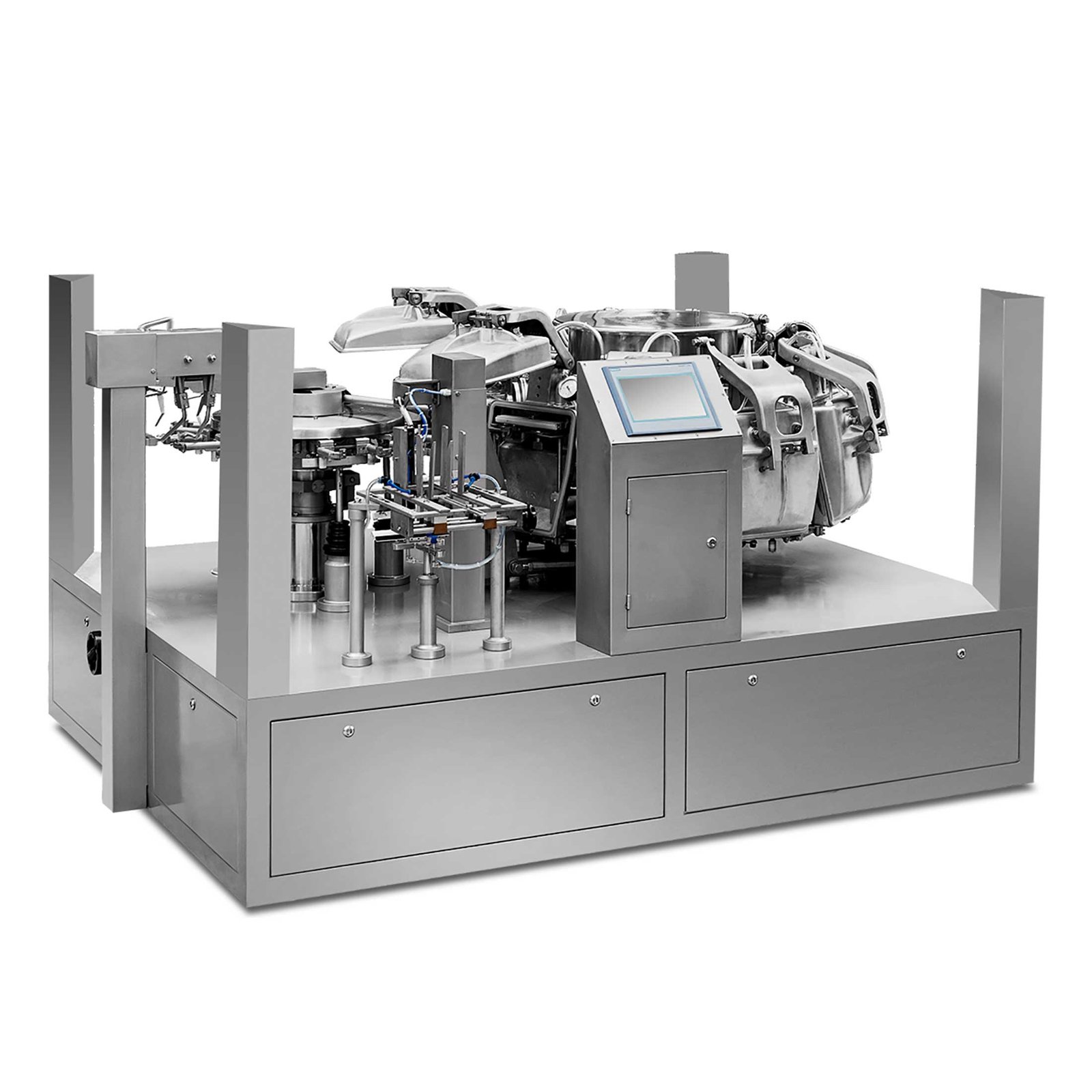

2. Nuts Coating Machines: A nuts coating machine is a piece of equipment used in the food processing industry to apply coatings or flavourings to nuts or other snack products. These machines are commonly used in the production of coated nuts such as chocolate-coated nuts, yogurt-covered nuts, sugar-coated nuts, and more.

3. Nuts Flavouring Machines : Nuts flavouring machine is a device used to add various flavours to nuts, such as peanuts, almonds, cashews, pistachios, etc. These machines are commonly used in the food industry to enhance the taste and appeal of nuts to consumers. The flavouring process is typically done by coating the nuts with a flavoured solution or powder.

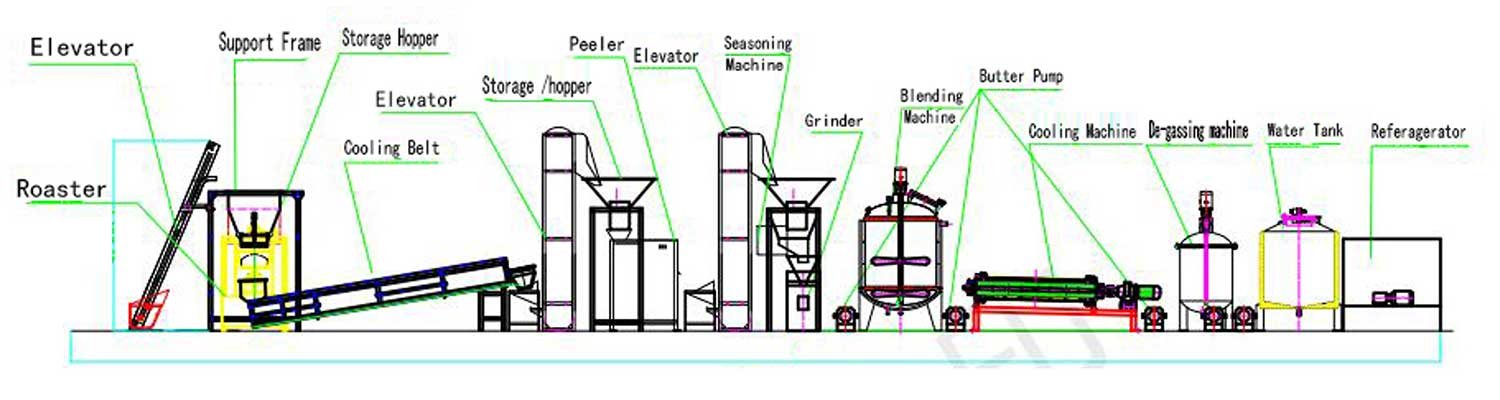

4. Nuts-Peanuts Butter Line : The Nuts-Peanut butter line uses roasted nuts, which are fed into grinding mills to produce crunchy and healthy nuts butter. Depending on the desired product, you can add additional ingredients like sugar, salt, oil or flavouring during the mixing process Nut processing starts with cleaning, sorting, and grading the raw peanuts to remove any impurities. Then, the peanuts are roasted to enhance flavour and reduce moisture content. After roasting, blanching might be done to remove the skin. The peanuts are then cooled and sent for grinding.

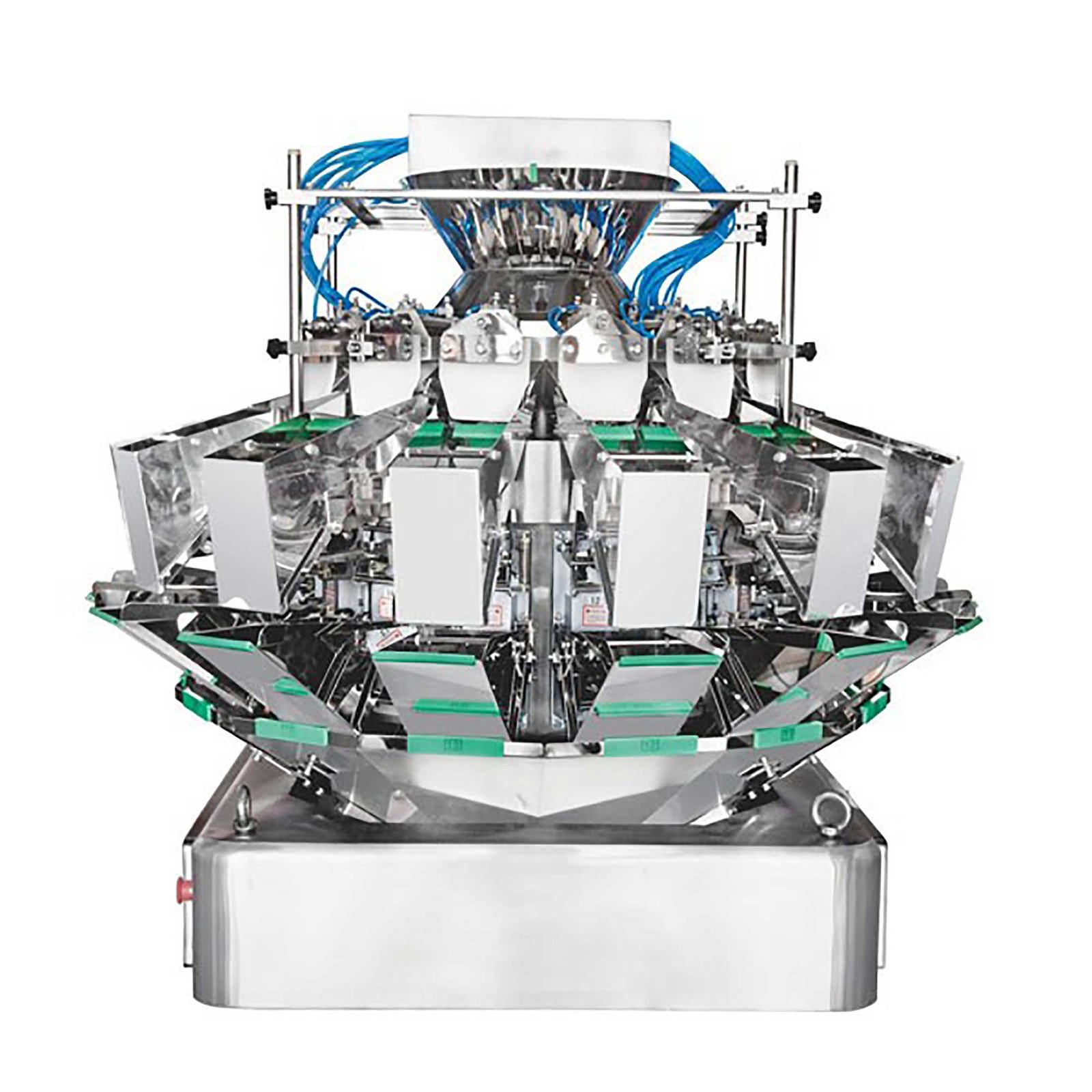

5. Cleaning and Sorting Machines: These machines are used to remove impurities, debris, and foreign materials from the nuts and dry fruits. They may include vibrating screens, air classifiers, and colour sorters.

6. Blanching Machines: Blanching is a process that involves briefly immersing nuts or dry fruits in boiling water and then rapidly cooling them. Blanching machines facilitate this process and help in easy removal of skins.

7. Grinding Machines: Grinding machines are used to process nuts and dry fruits into pastes or powders. They are commonly used in making nut butters, spice blends, and baking ingredients.

8. Drying Machines: Drying machines remove excess moisture from nuts and dry fruits, increasing their shelf life and preventing spoilage.

9. Oil Extraction Machines: Some nuts, like almonds or walnuts, are processed to extract their oils. Oil extraction machines are used to extract oil from these nuts.

For nuts with hard shells, such as walnuts or pecans, shelling machines are employed to crack open the shells and extract the kernels.

The specific machines used depend on the type of nuts and dry fruits being processed and the desired end products. In commercial food processing facilities, these machines are often integrated into a processing line, which automates the entire process from raw material intake to final packaging

Plant Layout - Peanut Butter

Suitable Product