End of Line Automation

Product category

Complete Robotic End of Line Automation Solutions

Case Packing and End of Line Automation is one of the fastest growing and most diverse applications of modern automation technology. The importance of preparing finished goods in an efficient and cost effective manner for delivery to the distribution channel, has never been greater, than in today’s global economy and markets.

End of Line Packaging Automation refers to the process of automating the packaging and palletizing tasks at the end of a production line. This automation is employed in various industries to streamline the packaging process, increase efficiency, reduce manual labor, and improve overall productivity.

End of Line Packaging Automation and Case Packing is one of the fastest growing and most diverse applications of modern automation technology. The importance of preparing finished goods in an efficient and cost effective manner for delivery to the distribution channel, has never been greater, than in today’s global economy and markets.

Our team with the help of world’s best designer and manufacturer of complete industrial automation solutions, is able to service large and small scale industries where we combine a competitive edge using high-tech quality features and low cost automation.

Our Portfolio can meet all automation requirements of – Engineering, Automobile and Ancillaries, Food and Beverages, Pharmaceutical, Solar, chemicals, Metals and various industries with flexible turnkey modular and energy efficient automation solutions. We are committed to provide total end-of-line automation solutions. We offer a complete service, from design, manufacture and project management through to implementation and ongoing service support.

End of Line Packaging Automation can be divided into many key technology categories. Not sure which technology to choose or need more information? Please don’t hesitate to Contact Us at any time. We are here to help!

Solution

The End of Line Packaging Automation typically involves the following steps

- Product Conveyance: Products coming off the production line are conveyed to the packaging area using conveyor belts or other automated transport systems.

- Inspection: Depending on the industry and product type, automated systems may inspect the products for quality control and ensure they meet specific standards before packaging.

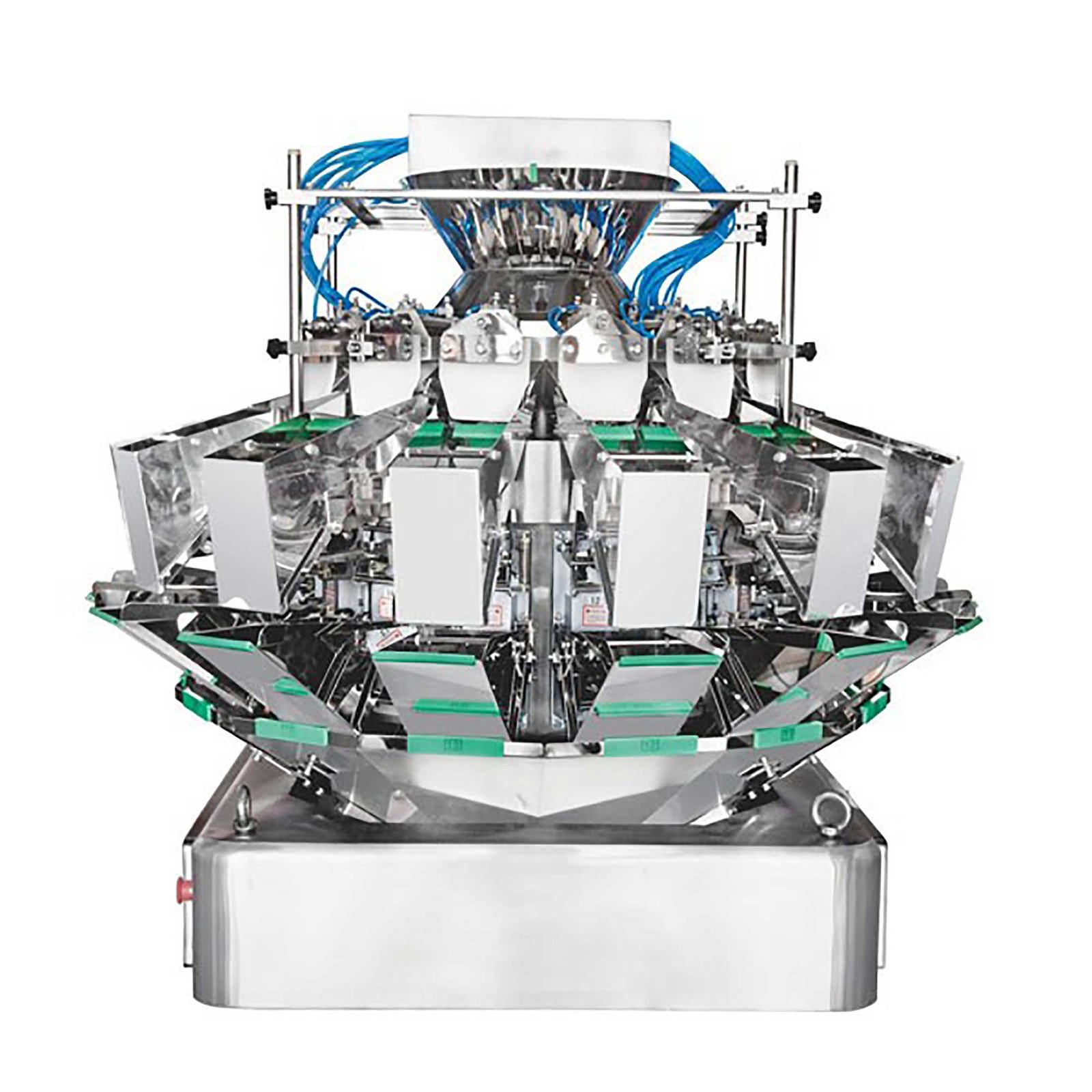

- Grouping and Accumulation: Products are grouped together in predefined quantities, either based on the packaging requirements or customer preferences. Accumulation conveyors are used to create batches of products.

- Packaging: Automated packaging machines are used to place products into boxes, cartons, bags, or other types of containers. These machines can handle various packaging materials and are programmed to perform specific packaging tasks efficiently.

- Labeling and Printing: Automated labeling and printing systems may be integrated into the packaging process to apply labels, barcodes, and other necessary information on the packages.

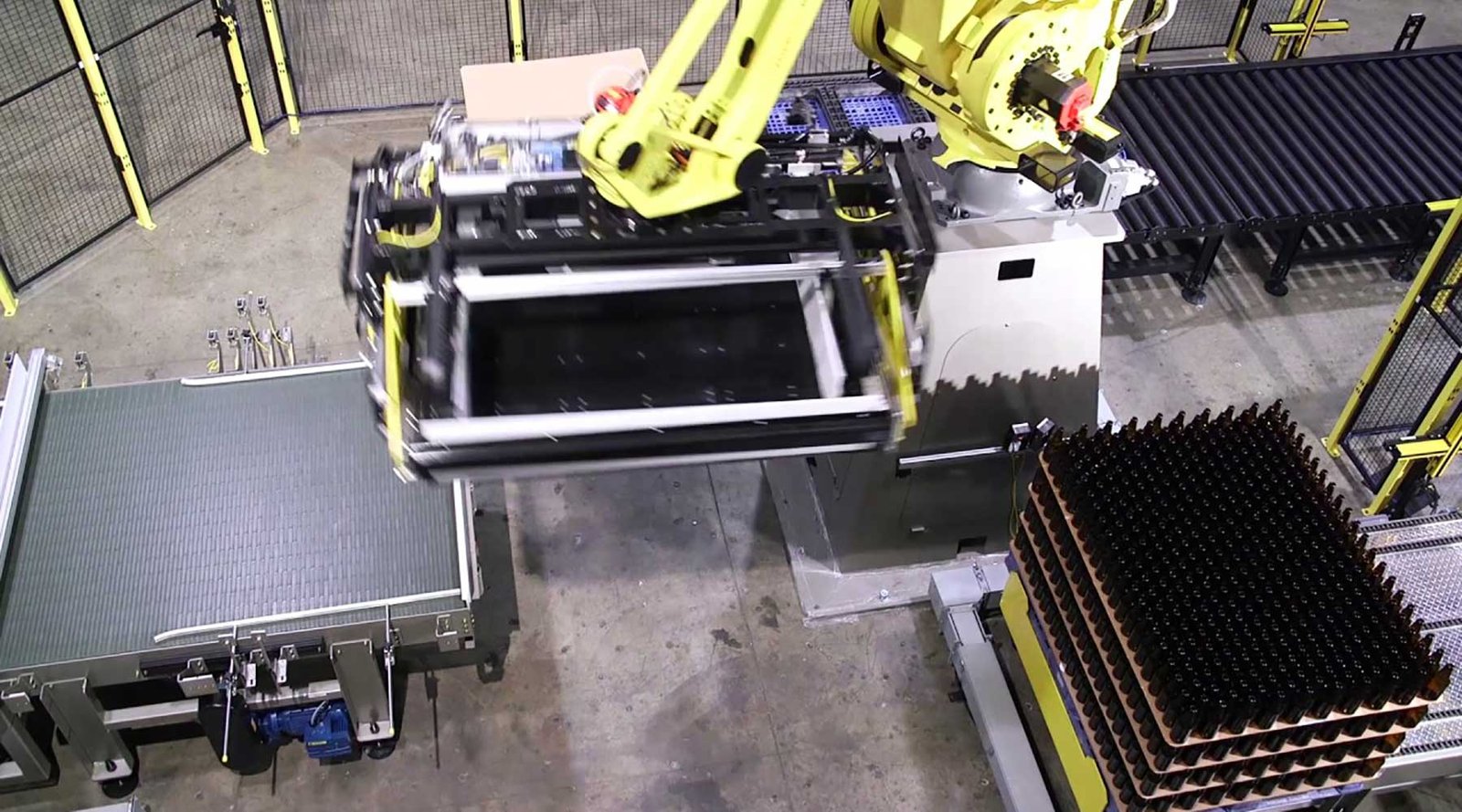

- Palletizing: Once the products are packaged, they are automatically transferred to palletizing stations. Robotic palletizers are commonly used to stack the packaged products on pallets in a precise and stable manner.

- Stretch Wrapping: After palletizing, the pallets are moved to stretch wrapping machines that secure the products on the pallet with stretch film for stability and protection during transportation.

- Transportation: The fully packaged and palletized products are then ready for transportation and distribution to retailers, wholesalers, or end consumers.

As these machines are completely custom make, it can be perfectly designed and delivered as per client’s specific requirements. For further detais please contact us..

Overall, End of Line Packaging Automation is a valuable solution for industries seeking to optimize their packaging processes and improve the overall efficiency of their operations. It is especially beneficial for companies dealing with high volumes of products or complex packaging requirements.

Benefits of End of Line Packaging Automation

- Increased Efficiency: Automation reduces the time required for packaging, which leads to higher production rates and quicker order fulfillment.

- Consistency and Quality: Automated systems can ensure consistent packaging quality, reducing the chances of errors and product damage.

- Labor Savings: By automating repetitive tasks, the need for manual labor is reduced, saving costs and minimizing the risk of injuries.

- Flexibility: End of Line Packaging Automation systems can often be reconfigured to handle different product types and packaging requirements, offering flexibility in the production process.

- Space Optimization: Efficient palletizing and packaging can help maximize warehouse space, leading to better storage and logistics management.

- Traceability: Automated systems can track and record packaging data, providing better traceability and accountability in the supply chain.

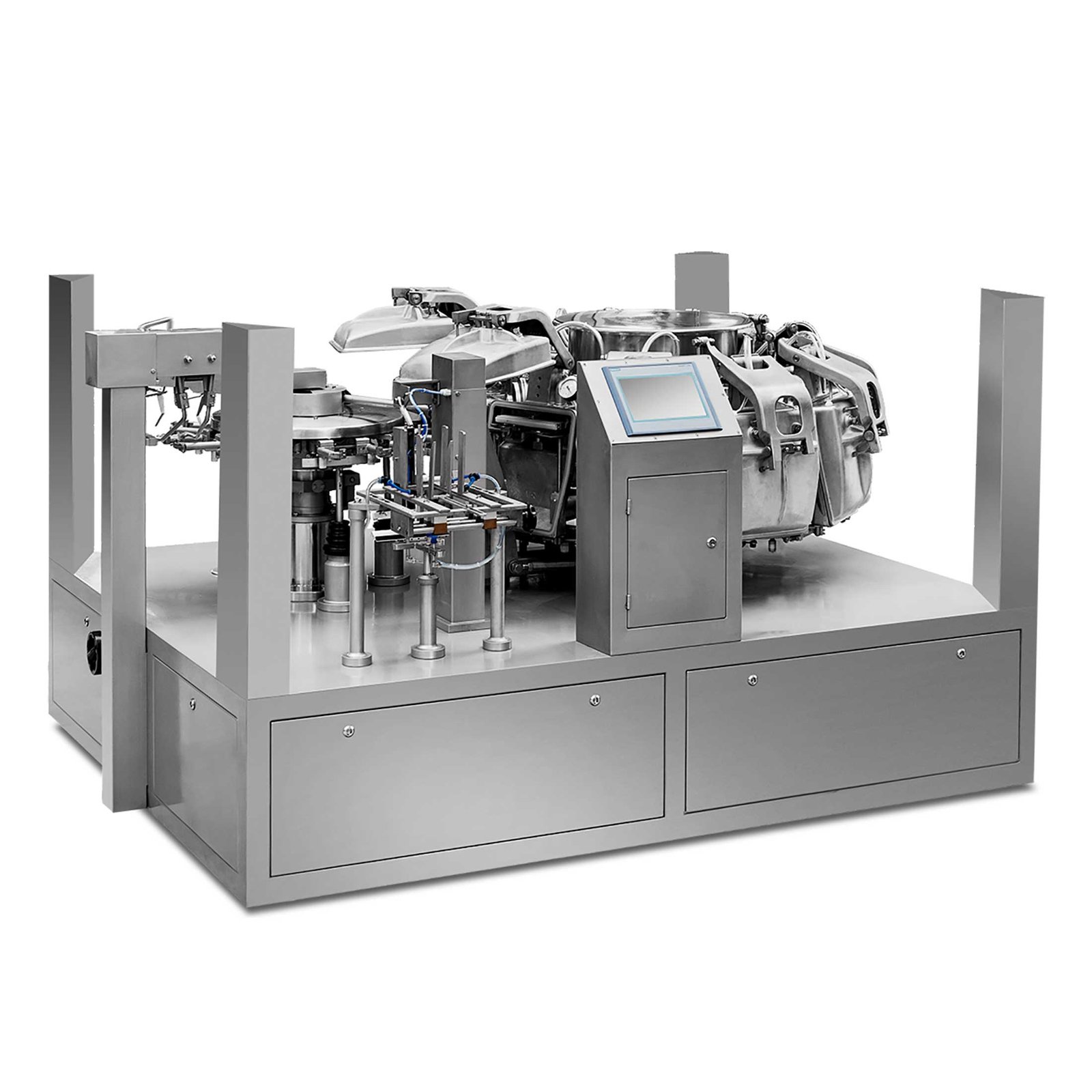

Our Expertise custom made End of Line Packaging Solutions for different industries. Small pouch in carton packaging is one of the ideal solution for the industries who want to pack different numbers of pouches in carton automatically as per pre-fixed pattern.

The Working process is designed for user friendly & easy operation. This error free solutions works as per following Process: Pouch feeding & Carton feeding → Pouch & carton in position → Vacuum fixture moving & pick Pouch → Vacuum fixture moving through two axis → release the bottle into carton → Carton left to sealer → Next Process.