Special Jar Packaging System

Product category

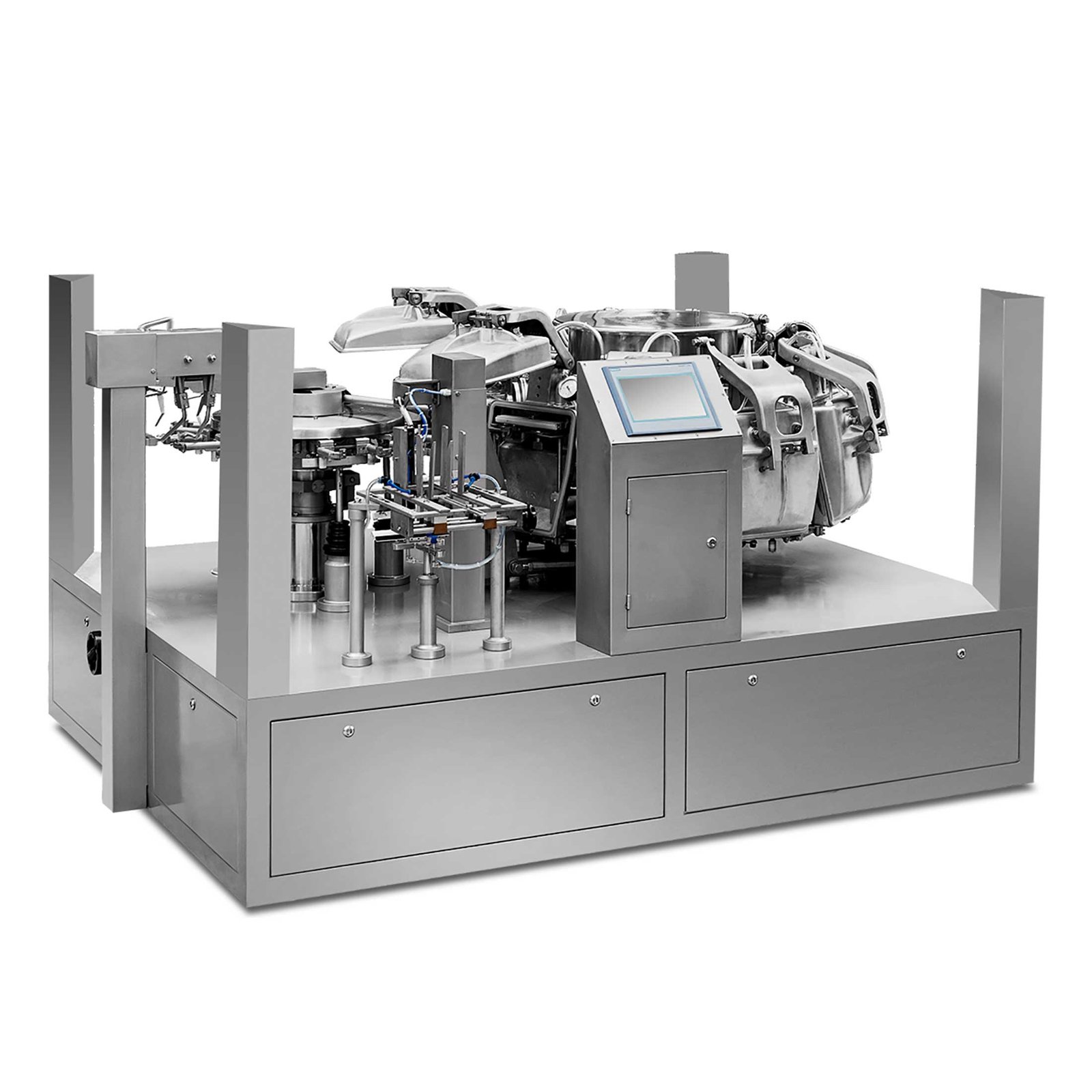

Automatic Customized Jar Packaging Machine

Fully Automatic Customized Jar Packaging Machines a type of equipment used in the food industry, pharma industry, cosmetic and FMCG Industries to automate the process of packaging. Designing and custom-making high-quality Automatic Customized Jar Packaging Machines requires a multidisciplinary approach and attention to detail. We work closely with the client to understand their specific needs, product types, packaging materials, production volume, and desired output. Gather all relevant information to develop a comprehensive understanding of the project scope.

After creating initial design concepts based on the gathered requirements, we use computer-aided design (CAD) software to visualize the machine’s layout, components, and functionalities. Ensure that the design is modular and adaptable for Automatic Customized Jar Packaging Machines for different product types. We choose high-quality materials for building the machine’s components. Stainless steel and food-grade materials are often preferred for applications involving RTE foods.

Customization for Each Product: As each product (cup noodles, snow sprays, aerosol spray, RTE foods) has unique packaging requirements, tailor the machine to handle the specific filling, sealing, and labeling needs of each product. This may involve using different filling mechanisms, sealing technologies, and label applicators.

Enquire Now

Suitable Jar

Some of the Customised jar - Bottle Packaging Options

- RTE Food Cup Packaging Machine

- Sprinkler Jar Packaging Machine

- Snow Spray Packaging Machine

- Paint filling machine

- Lubricating oil filling machine

- Noodles Cup Packaging Machine

- Lug Cap Bottle Packaging Machine

- Party Spray Packaging Machine

- Gel Filling Machine

- Cheese filling machine

- Rice Cup Packaging Machine

- Perfume Packaging Machine

- Aerosol Can Packaging Machine

- Bucket FIlling Machine

- Glue Filling Machine

Some Features of our Automatic Customized Jar Packaging Machines

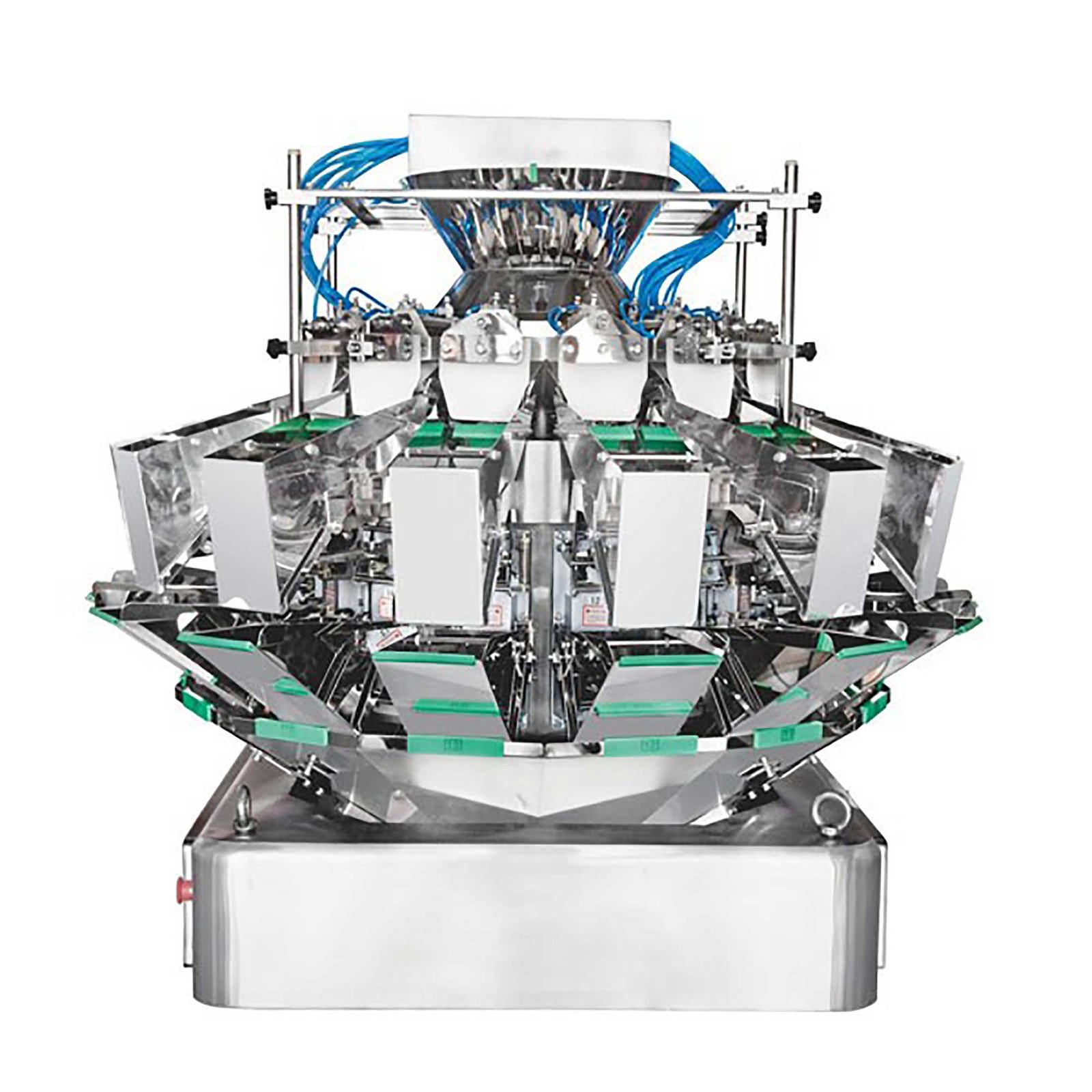

- Automation and Control Systems: Incorporate advanced automation and control systems to ensure precision, accuracy, and consistency in the packaging process. Use sensors, actuators, and programmable logic controllers (PLCs) to monitor and regulate the machine’s functions.

- Hygiene and Sanitation: For food products, prioritize hygiene and sanitation. Implement easy-to-clean surfaces, smooth edges, and removable parts for thorough cleaning between production runs.

- Testing and Quality Assurance: Conduct rigorous testing and quality checks at various stages of machine development to ensure that it meets performance and safety standards. Test the machine with different product types to validate its versatility and efficiency.

- Safety Features: Integrate safety features, such as emergency stop buttons, safety interlocks, and protective guards, to ensure operator safety during machine operation.

- User-Friendly Interface: Develop an intuitive user interface that allows operators to control and monitor the machine easily. Clear instructions and troubleshooting guides can enhance productivity and reduce downtime.

- After-Sales Support: Provide comprehensive after-sales support, including training, maintenance manuals, and technical assistance, to ensure the client’s satisfaction and smooth operation of the packaging machine.

Our experienced packaging engineers, experts in automation, and industry professionals can enhance the development process and lead to the creation of a high-quality, customized packaging machine that meets the client’s needs with precision and perfection.

Automatic Customized Jar Packaging Machine are the perfect solution for packaging of all type of Pet-Tin-Glass Jars irrespective of it’s shapes and sizes. These Machines streamline your operations and increase output. These latest and innovative Jar Packaging Machines can also perform online vacuum with more advance system. The end result – your packaged product looks modern, offers convenience, and differentiates itself from your competition.

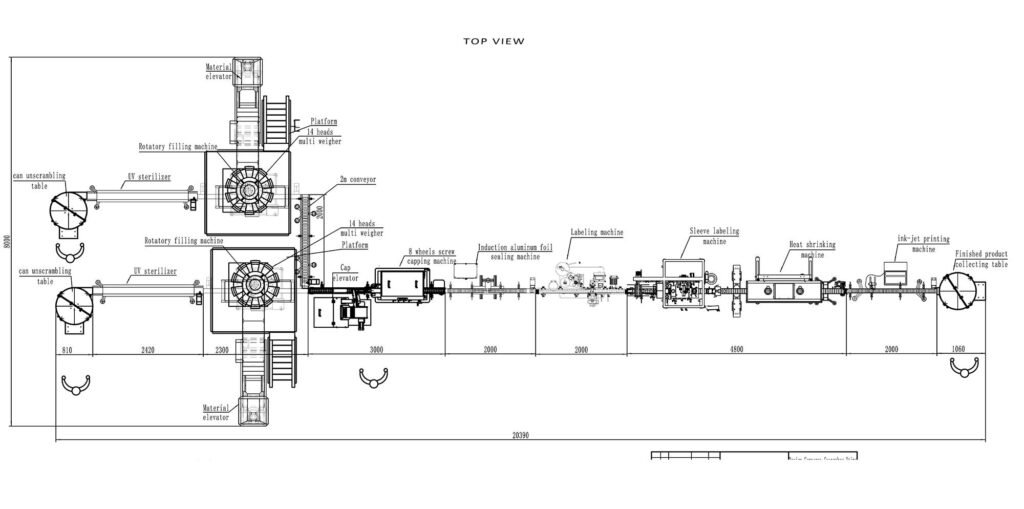

Packaging Layout

Suitable Products