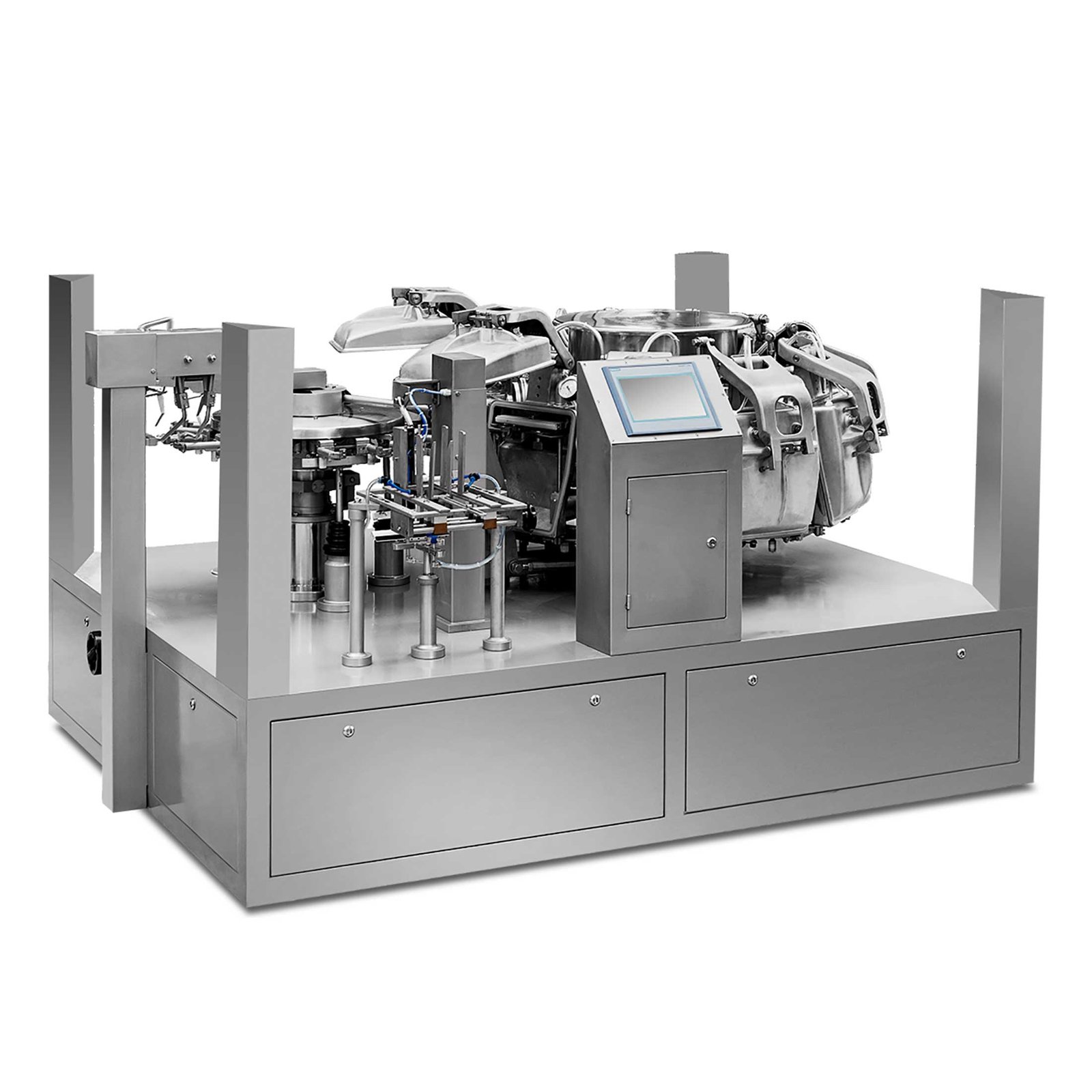

Rotary Pick Fill Seal Machine

Product category

Range of Rotary Pick Fill Seal Machine

4th Gen

PFS Packing Machine

Beautiful Packaging

Upto 45 Bags/Min

Premade Pouch Packaging Machine can pack most products with a fast speed. Choosing suitable premade bags can greatly improve the appearance and ease of use for consumers.

Large Bag

PFS Packing Machine

Best for Large Packaging

Range 1-5 kgs bags

Model designed to cater the need of large bag packaging ranging 1-5 kgs, perfectily suitable for Rice-Pulses-Flour-Grain industry who need packaging solution for upto 5 kgs premade bags.

Air Suction System

PFS Packing Machine

Compact Yet Powerful

Perfect for Nuts & Dry-fruits

These types of machines are a variant of the rotary premade pouch packaging machines that include an additional air suction system to semi vacuum the product to increase the self-life.

5th Gen High Speed

PFS Packing Machine

High Performance – Higher Productivity

Upto 65 Bags/Min

Latest 5th Gen Rotary Pick Fill Seal Packaging Machines have attractive and modern design perfectly suits the production floor who requires highest performance and productivity.

Retort-Ready to eat

PFS Packing Machine

Retort Pouch Packaging

Perfect for RTE Foods

This particular PFS Machine allows manufacturers of RTE foods to conveniently pack their perishable products, safely, in a wide variety of Retort Pouch, which can then be subjected to retort for longer shelf life.

Non Wovan Bag

PFS Packing Machine

Unique and Powerful

Bulk Packaging 2-10 Kgs

These machines use a rotating turret to pick up, fill, and Stitch Premade Non-Wovan bags. Topping the best in class machine in it’s segment provide unique solution of Rice-Grain-Flour Industry.

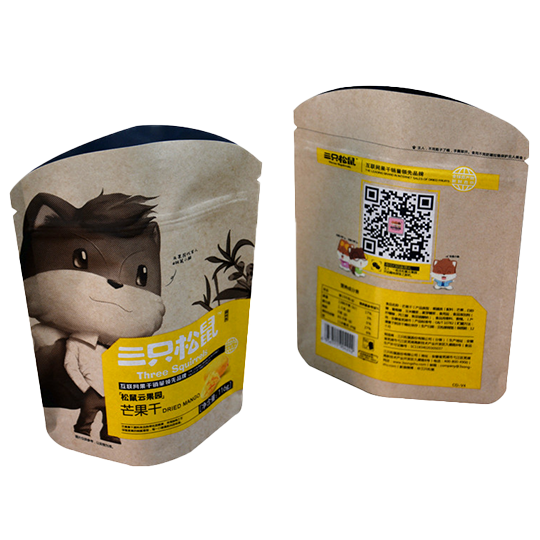

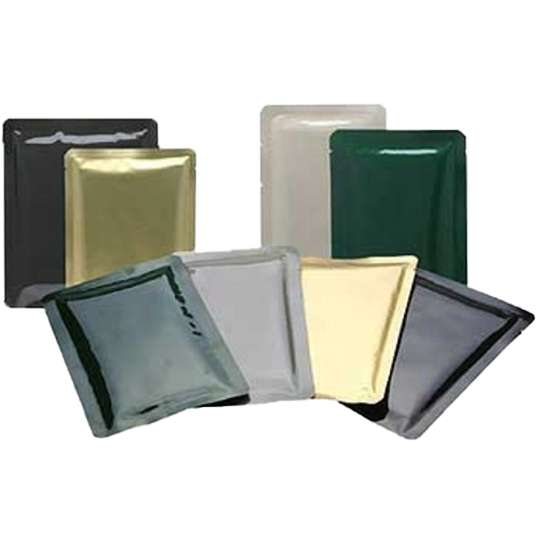

Types of Bags Suitable for Rotary PFS Machine

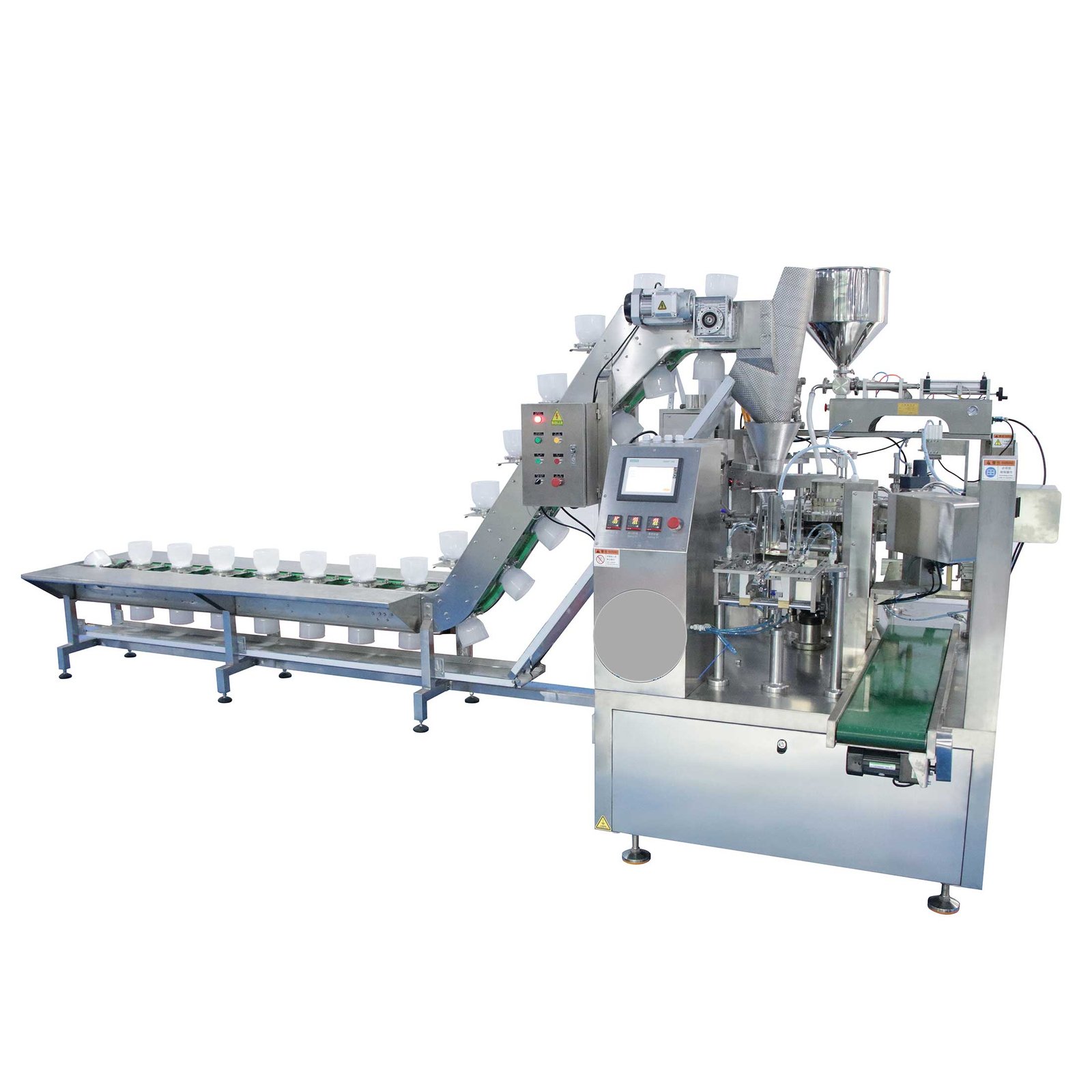

Rotary Pick-Fill-Seal Packing Machine

Imperial Associate’s Rotary Pick Fill Seal Machine is also known as the Namkeen Packing Machine. These machines are the perfect solution for premade bags. Our Rotary PFS Packaging Machine is designed to optimize your packaging processes. These machines help your business run smoothly. Increase production by up to 50 percent with premade pouches. Unlike VFFS machinery that uses roll stock film to make bags, our premade pouch packing machines offer something completely different.

Our machines are made of stainless steel, which ensures longevity and reliability. This machine is completely automatic, which means one or two workers can control it easily.

These latest and innovative packaging machines, Pick-Fill-Seal, already prepare custom pouches, so no rollstock is required. It can also vacuum online with more advanced systems.

Which makes your packaged product look modern, offers convenience, and differentiates itself from your competition.

Features include:

1. Incredibly easy to operate and maintain with a smart interference program.

2. Package anything from Snacks & Confectionery, to Grains & Granular, to Paste & Liquids, to pet foods, to powders, to legal cannabis products

3. Easy integration with different types of filling systems, infeed and outfeed conveying equipment, inspection systems to secondary packaging machines.

4. Perfect and accurate Rapid sealing System

5. The latest Siemens/Mitsubishi and other internationally renowned components and servo drives

6. Durable & Waterproof stainless construction

7. Can pack any type of Premade/Preformed Bag like Zipper, Standup, Doy Pouch, Special Shape, Flat Bottom, Gusseted, Slider, Spout, 3 Side Seal, etc…

Features of Rotary PFS Packing Machine.

Our Rotary PFS machine has been made by using today’s modern technologies. Which is the perfect option for your business. The few parts that make us different are given below:

Stainless Steel: Our company does not compromise on quality for the customers. Our machines are made of stainless steel. Since the machine is made of stainless steel, it lasts for a long time without much maintenance. Or provides resistance to corrosion and ease of cleaning.

Fully Automatic Operation: Our pick fill seal machine are fully automatic. Therefore, you do not need many workers to operate them. One or two workers can easily operate it. The advantage of automatic machines is that they allow seamless operation with minimal human intervention. This increases efficiency and productivity.

Customizable production capacity: We make machines with customizable production capacity, keeping in mind the requirements of the customers. The result is that the customer can increase or decrease his production capacity according to his needs.

Low Maintenance Requirements: Machines manufactured by Imperial Associates require minimal maintenance. The advantage of this is that you only need to concentrate on your business. This is how your business grows.

High production capacity: Our machines are capable of making 60-70 pouches per minute. But the customer can customize it as per his requirements. After purchasing this machine, you can run any big or small-scale business. These machines are suitable for both types of businesses.

Control System: Many PFS Packaging Machines come equipped with the best control system that oversees the sealing, labeling, and fitting of the packaging, guaranteeing proper functionality.

PFS Machine Process

1. Giving Bag – Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date Printing – According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Opening Bag – While the suction cup opens the opening of the packaging bag, the air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

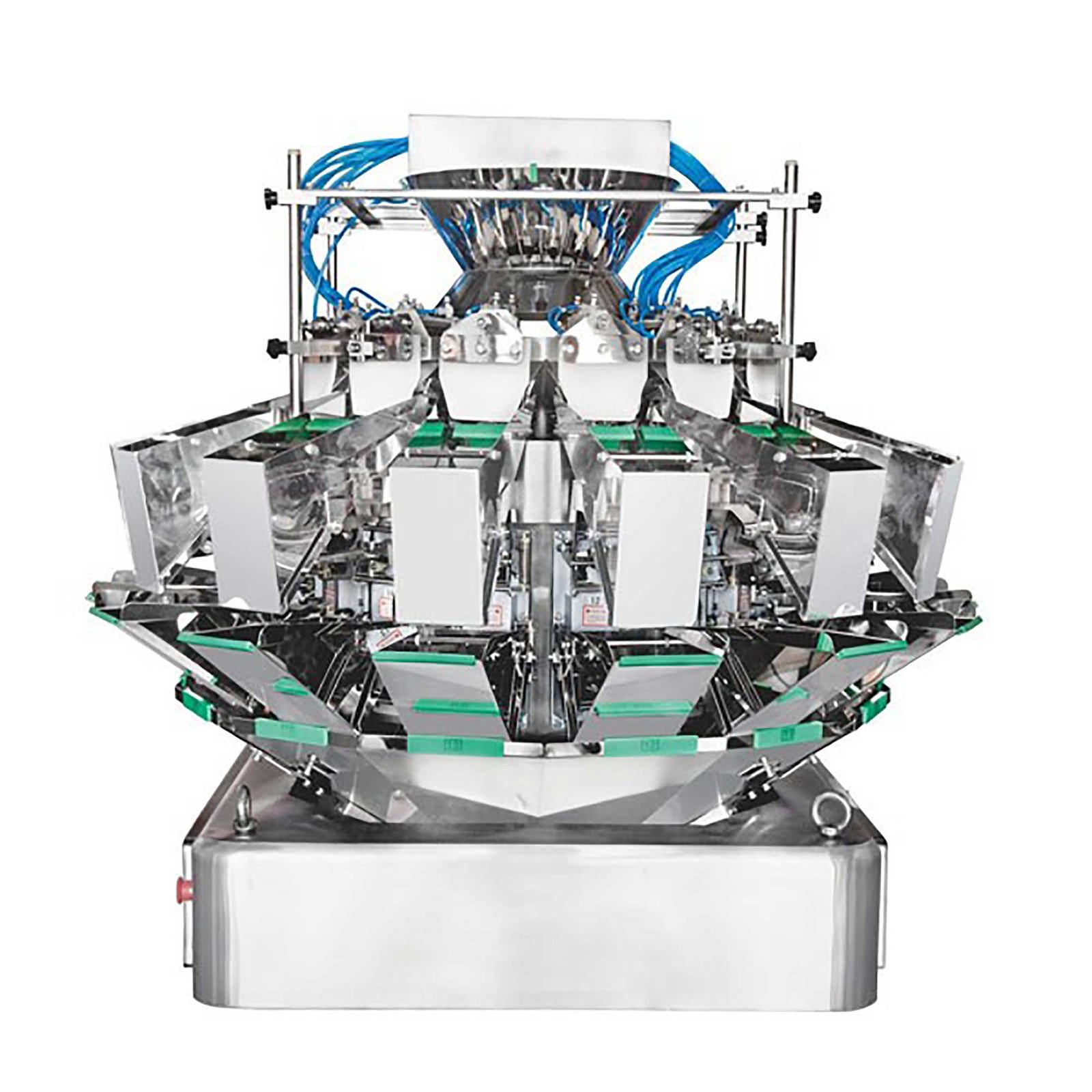

4. Filling & Consolidating – According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Buffering (or Other) – Nitrogen Dosing – Zipper Closing

6. Heat Sealing 1 – To seal the pouch or bag mouth with a couple of heat sealing air bars, the sealing pattern you can option, net or straight lines.

7. Heat Sealing 2 – To make the sealing stable and preventing from wrinkling with a couple of cold presses, then output the finished production automatically.

Suitable Products

1. Liquid – Handwash, Detergent, Yellow rice wine, Soy sauce, Rice vinegar, Juice, Tomato paste, Peanut paste, Fruit paste, Chili sauce, Bean sauce, etc.

2. Granule – Ready-Premixes, Crystal MSG, Granule medicine, Capsule, Seeds, Raw Chemistry material, Sugar, Chicken essence, Melon seed, Nuts, Pesticides, Fertilizer, Feed, etc.

3. Powder – Ready-to-Cook Premixes, Flour, Flavoring, MSG, Milk powder, Glucose, Washing powder, Raw chemistry material, White sugar, Pesticides, Fertilizers, etc.

4. Solid – Dry-Fruits, Pulses, Rice, Candy, Red dates, Oatmeal, Chocolate, Cookies, Peanut, Green soybeans, Rock candy, Pastry, Namkeen, Commodity, Puffed food, etc.

Advantages of Buying a Rotary PFS Packing Machine

If you purchase a Rotary Pick Fill Seal machine from New Imperial Associates P. Ltd., then you get some benefits, which are as follows:

24/7 Customer Support: Our support team is available for you 24/7. You can call us anytime in 24 hours. At Imperial Associates, we take special care that our customers do not face any kind of problem.

Business Guidance: Our team will guide you from packing to starting your business. You will be taken care of completely until your business becomes a brand.

Cost-effective price: We have kept the price of our machines in such a way that even a person starting a business can afford to buy our machines. Our prices are different from many famous PFS Packing Machine manufacturing companies.

Best quality: At Imperial Associates, we provide machines made with good quality. The result of this is that people focus only on the growth of their business.

Variety and Flexibility: Our machines can pack different types of premade pouches such as zipper, stand-up, doy pouches, special shape, flat bottoms, gusseted, sliders, spout, 3-side seal, etc. This variety and flexibility make your product stand out in the market.

Conclusion

The PFS Packing Machine is an integral part of the packaging of Rotary Pick Fill Seal Machine once they are manufactured, providing an efficient and reliable result for packaging of colorful spice blends. The entire machine is made of stainless steel and complies with FASAI norms.