Blister Thermoforming Machine

Product category

Blister Thermoforming Machine

Blister Packing Machine

Fully Automatic

Form-Fill-Seal-Cutting

These machines are designed to ensure the precision and integrity of the blister packs.

Colour blister Packing machine

High-speed production

Ensuring efficient packaging

It is a specialized packaging equipment designed to create blister packs for chocolates.

Suitable Packaging samples

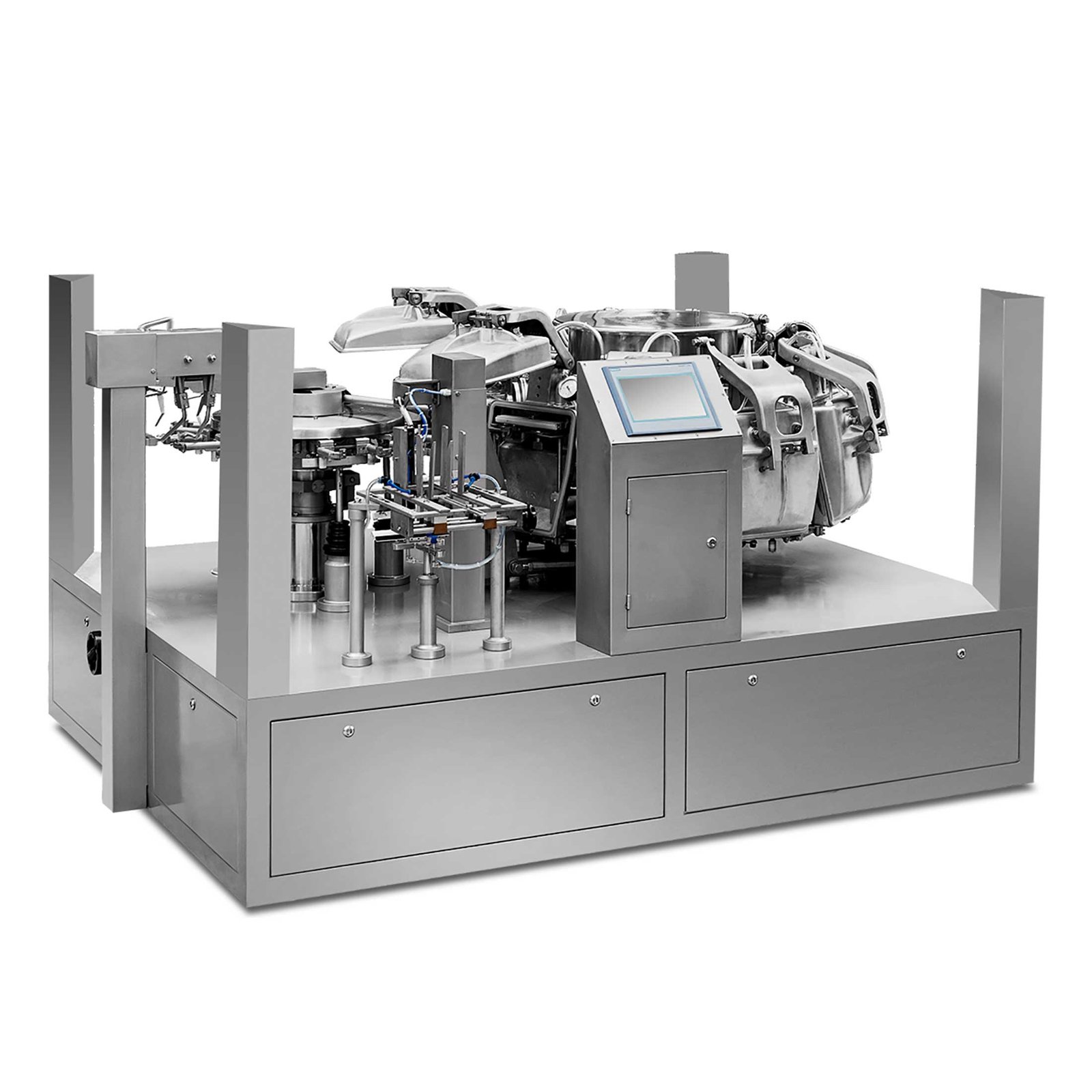

Blister Thermoforming & Tray Sealing Machine

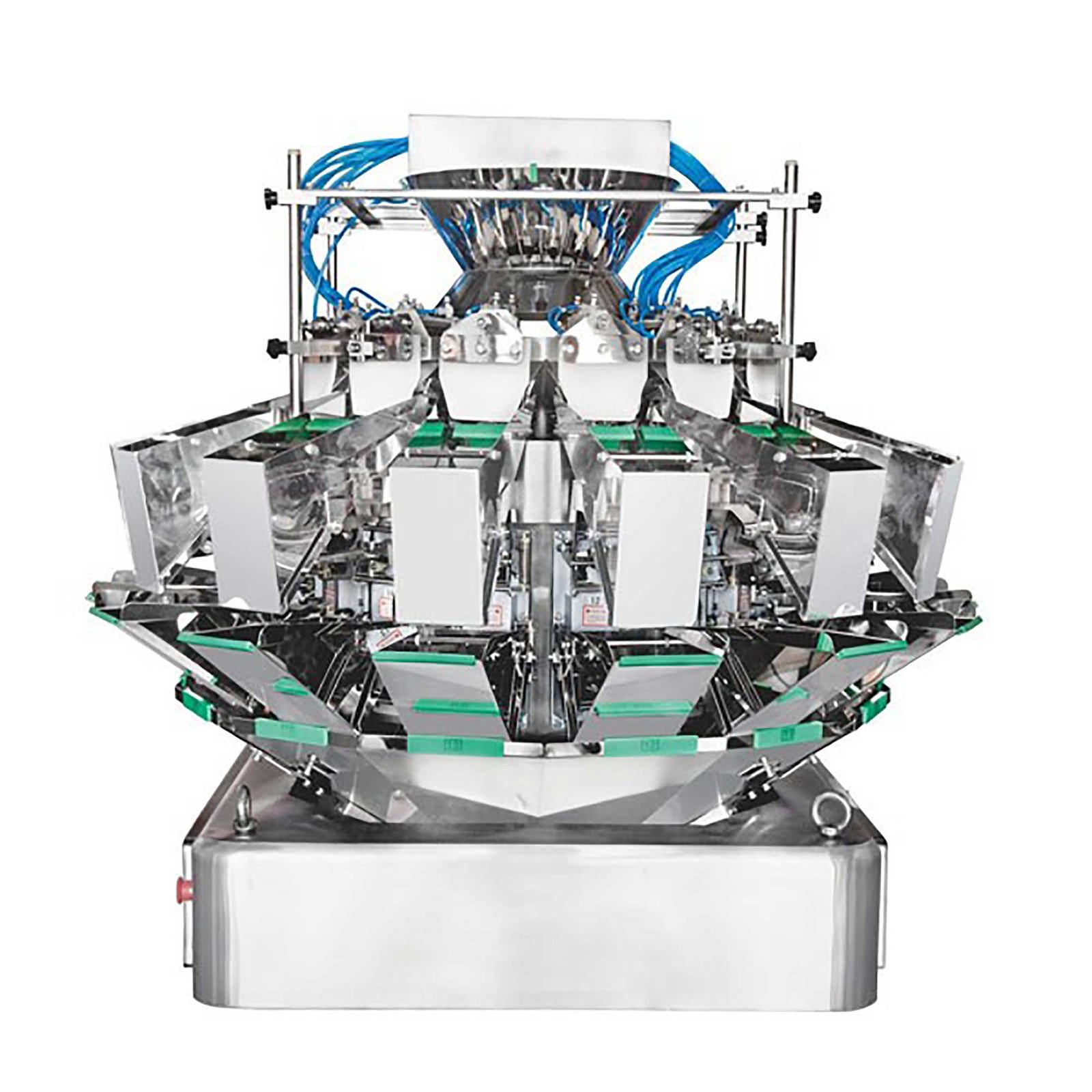

Imperial Brings the complete range of Trays, Cup, Glass Blister -Thermoforming and Fill-Seal Machines, which are suitable for different food industries like Pickles, Dry-Fruits, Jelly, Juices, Dairy Products, Fruit Jam, Butter, Ketchup, Fresh Syrup, Ready To Eat Food, Cheese, Dips, Confectionery, Mayonnaise, Honey, Dry Fruits, Meat, Dates, Fresh Fruits & Vegetables Etc. and so on.

These machine can form the tray-cups automatically from blister then fill-MAP-Seal in different shapes and sizes as per client need. These machines are specialised not only makes the cups/tray & sealing but also do Automatic Cup Washing, Feeding, Fillings, Sealing & Coding online.

These machines are of high performance and effectiveness. The product know-how allows us to standardize the “special”, thus being able to meet the increasing demands of every single product.

Range of Thermoforming & Tray Sealing Machines

- MAP Packaging

- Vacuum chamber machines

- Automatic tray sealing machines

- Automatic thermoforming machines

Our company is able to respond quickly and with cutting-edge technical skills, quality products and experience, to the needs of the market, covering the entire Food Packaging value chain. Imperial provides THERMOFORMERS and THERMOSEALERS, which thermoseals even in modified atmosphere (MAP) Skin every type of tank (aluminum, PE, PP), as well as the establishment of complete lines for each type of product. We provides automatic and semi-automatic machines for vacuum and for thermosetting.

Imperial produces a complete set of unstacking, dosing and end of line so as to ensure every type of packaging required. And with no distinction between solid and liquid and semi-liquid. Our range allows the closure in a modified atmosphere up to 13 cycle closing minute, with 8/10 trays per cycle. This allows packaging solutions up to 6.000/8.000 trays per hour.

Our machines are of high performance and effectiveness. The product know-how allows us to standardize the “special”, thus being able to meet the increasing demands of every single product. Imperial is able to sustain workload peaks while maintaining service levels, leveraging on its network of mechanical and services companies. Our’s technical support, combined with the cutting-edge modes of communication, enables us to provide equipments capable of interacting with our technicians around the world. This allows us a work of synergy between our customers and our engineers. The industry experience and the research for new solutions with customers make Imperial a really innovative company in the world of packaging.